3 - Drystack block surface bond cement for do-it-yourself walls

Drystack concrete block and cinder block technique uses surface bonding cement SBC instead of mortar for waterproof high thermal mass HTM thermic walls that are much stronger than conventionally laid mortar block walls. SBC 'stucco' with horse hair and calcium carbonate was used hundreds of years ago to build huge water storage cisterns. So it should be nothing 'new' to an experienced engineer. SBC is commonly required by local building code for sub-grade mortar block walls to ensure integrity. With dry stack construction, only the first course is bedded in grout on the footer to establish plumb and level for the wall. The rest of the dry stack block courses are laid without need for any mortar between blocks as long as they are of uniform size. Should you have poor quality block in your area, a thin coat of mortar can be added wherever needed to bring wall back to plumb. No need for importing expensive special 'interlocking dry stack blocks' when you are dry stacking with SBC. Locally sourced common concrete or cinder blocks are fine.

Dry stack block with SBC was never the primary focus of our HTM design, simply an economical construction option for homeowner-builders. Other thermic wall building materials are functionally as effective: concrete, rammed earth, adobe, superadobe, and slag, stone, or bag walls. SBC is featured here given its ease of construction and better acceptance among engineers, building officials, mortgage brokers, and insurance companies. Engineering can be identical to mortar block walls common to commercial buildings, with SBC adding waterproofing and a great deal of torsional strength.

Blocks for dry stacking with surface bonding cement do not need to be of any special design. They don't have to interlock, and best of all you don't have to know how to lay block. You simply stack the concrete blocks in a running bond pattern and then parge coat both sides with a single layer of fiber reinforced, surface bonding cement. Applied 1/8 inch thick minimum to both sides, surface bonding cements have strengths that are superior to conventionally mortared block walls and they look a lot better too without any grout lines. Once your block walls have been surface bonded, hollow vertical cores (minimum every four foot and alongside every opening) are filled with ready-mix concrete grout and a #5 rebar for an exceptionally strong heat storage mass. While possible to rely upon SBC for flexural strength in excess of standard mortared cinder block wall construction, it is rare to see an engineer scale back rebar reinforcement. SBC is much easier for unskilled homeowner builders without any experience laying block and can make excellent use of large volunteer work crews for a 'barn raising' to speed construction.

Solid, poured in place, concrete walls are every bit as effective, but forming and pouring is outside the skill level of most people. Hiring contractors to build the forms, pour the walls and then return to strip the forms, is always an option when you have money in the budget. Empty cores in your block walls (those not having structural rebar) should be filled with cement grout, sand, or compacted soil for extra thermal mass. There is no advantage to having empty cores in the block walls and absolutely no advantage to filling the cores with insulation. The more thermal mass in a home, the better. Most clients simply order more concrete grout and fill the empty cores while they fill the structural cores, but some clients opt for using sand or dirt excavated from the job site. The only caveat to using soil to fill the empty block cores is to compact well and cap the top of the core with SBC or mortar to prevent moisture from penetrating.

One key to thermal performance and indoor air quality is to waterproof walls to guard against moisture transference and surface bonding cement was originally designed to line water cistern tanks. You need to prevent water from traveling through the home's walls, sucking away energy and presenting possible indoor air quality problems. The same applies to poured-in-place concrete walls: the wall needs to be waterproofed on both sides to prevent water transfer. Several coats of low VOC non-porous latex paint is a good solution for waterproofing the interior of a concrete wall. The exterior footers and wall need a minimum of two heavy coats mop-on waterproofing treatment or better yet, a roll roofing underlayment sheet bithumin, like Grace® Ice and Water Shield.

Water and waste lines are best run through stick-frame partition 'wet walls' in floorplan layout. But plumbing and electrical can be run through the block wall cores, if need be. Wiring in concrete block or poured-in-place concrete walls involves running conduit pipe down through the cores or forms before the pour and then pulling wire later to all outlet and switch boxes. In-floor electrical outlets like you see in commercial buildings are an option for electrical, as are surface mounted Wire-Mold® power strips. A visually pleasing and labor-saving ways to run some wiring is shown here with half-round logs routered out along the back and holes cut for outlet and switch boxes. Nice design touch that does not require that much carpentry skill.

With any surface bonding cement, conventional mortared block, or poured-in-place cement wall, key is:

* do not fill block cores with insulation or foam. This is counter to what you are trying to achieve. The empty cores should be filled with concrete, sand or some other solid thermal mass material.

* vibrate the newly poured wall cores thoroughly to avoid air pockets. These tools are relatively inexpensive from companies like Harbor Freight Tools. Removing air pockets from structural concrete filled cores is very important for ultimate wall strength.

* interior walls are surface bonded, so there is no need to stucco or drywall. You can do a finish coat of stucco to attain a particular texture, though, or use a synthetic stucco mixture.

* always coat the exterior and interior of your walls with waterproofing. Water absorption and transference must be stopped to maintain interior air quality. A high quality non-porous latex does wonders.

* exterior insulation on the walls must be surface bonded with a latex modifier added to allow it to stick to the EPS foam. Reinforce with galvanized chicken wire or expanded lathe for structural integrity.

If you are not familiar with laying block (mortared or surface bonded), after the corners are stacked six to eight rows high, setting the string line is critical. The corners dictate the walls between. Starting from corners, you simply stack block between. You can alternate last blocks, but it is generally the center block and it rarely needs shaved to fit. There are probably as many different ways to knot the line block as there are masons. Xing at the knuckle (full corner end of wooden line block) certainly helps stabilize or you can just wrap the string once or twice around block lengthwise, then anchor back to pin. You can pull in slack a lot easier this way, cinching to line pin, plus it ensures the string line will remain taut and true. While it is possible to simply set the wood line block on corner and tie off with tension alone, having an anchor post pin as shown is a little more elegant and saves the string from being subject to jumping off.

As with almost everything in life, there are at least two opinions on the correct usage of the string line (mason line). Most prefer to keep string line a set distance from block (5/8 inch as pictured above with the Marshalltown® line block). This allows you to use your fingers as a quick spacer - as soon as fingers touch line, you know you are about true for stacking. Classic masonry with grouted courses, forces you to hold the block at center pull / cavity opening (fingers inside block to steady and drop plumb). You can't always be looking down on the block, though, and you really don't need to with dry stack. Some masons like the string line right where the blocks are going. You just have to maintain clearance, even if only 1/16 inch, to keep true. Nothing should ever touch the string line or it is compromised. It is possible to keep the wall plumb (vertical) and level (horizontal) without a string line reference, but the only way to keep it straight (true) is with a string line. Wander 1/16 inch off true every coarse and you will find the wall with a 1/2 inch error before you know it.

The beauty of dry stack SBC versus mortar block is not having to make sure each and every block is plumb, level and true before setting the next block. When you are rolling along with stacking the block, you never stop to check every single block. You lay the course just shy of stringline true and then come back to adjust over to the line. A large rubber mallet does a quick and efficient job of trueing the wall until you get two or three courses atop the errant block. This is where you notice the great strength provided by friction with six blocks touching the one you want to move and gravity at play. After the surface bonding cement is applied and structural cores filled, an SBC wall is much stronger than a comparable mortared block wall.

A major time saver is never cut any blocks for the layout so you should design around using all full and half blocks. Block layout we normally work with is eight inch wide block (8" wide, 15.625" long, and 7.625" tall). Maintaining a running bond stack where the upper block overlaps half of lower block is easy with eight inch wide since the corner turns on 1/2 of the width (15.625 inch long and eight inch wide). When the design requires changing to 12 inch wide block (berming into a hillside) you suddenly need to cut a block every other course. The first course is traditionally all full blocks (12 inch by 15.625 inch long). The second course (as shown below) uses a cut block - one 4 inch and the other what is left over (about 11-1/4" to 11-1/2" long). Half blocks are used at the end of a wall or doorway opening, not in a corner or on a straight wall run between two corners.

One key to SBC or any other Portland® cement based stucco, concrete or mortar is to keep the finished material moist for the first few days of curing. Any cement based product needs to cure slow and steady for optimal full-strength and that can take up to a month for a concrete slab. If you want a quality product, get several hand pump sprayers for misting water during construction. Tent and heat the first course with mortar bed and keep it moist for the first few days of set, especially when temperatures are going to dip below 50 degrees. The same applies to any SBC work later. When dry stacking or mortar block laying in a cold climate, you should consider covering the entire structure with string reinforced poly sheeting. The tops of block walls can be spanned with a few beams and clear tarp material draped across all walls. Common roll size is 20' by 100', with 40' by 100' available in some areas. There is also a woven mat material. Commercial projects often leave the plastic tent in place for the entire construction, cutting away with razor knives after the ceiling has been oiled and interior is ready to work. Then the clear tarp just falls to the floor and becomes a drop cloth to keep traffic off concrete.

Dry stacking is addressed on our website as a courtesy to our HTM clients interested in alternative high thermal mass wall construction techniques and not something we specialize in. Legal liability dictates engineering details are site-specific and dependent upon site and soil conditions, local building code, and the floor, wall, and roof construction methods. If the manufacturer of surface bonding cement being used is not able to provide construction advice for their product, it is best practice to hire a local structural engineer. Unfortunately, we are not able to provide such services.

Surface bonding cement SBC dry stack concrete masonry unit CMU block wall and monolithic foundation details are typical and common to any size building, but will naturally vary depending upon size of structure, soil and site conditions, and local building codes requirements. Conservative engineering practice is to design SBC wall reinforcement (rebar) in the same grid pattern as a mortared block wall, given site, soil, and foundation variables. In high thermal mass construction, it is standard practice to fill all cores. No hollow cores in an HTM. Non-structural cores can be filled with sand or similar. But in practice, if you are 'shooting cores' with a pumper truck, it is sensible to just go ahead and pour all cores with concrete 'grout' while you have the machinery on site. We no longer provide construction, consultation, or engineering services and any information presented on this website is for 'entertainment purposes only'. Site, soil, and local code requirements are only the first of many unknown variables. We do not warrant information for any errors or omissions. Plans are not presented as construction ready. Local engineering approval must always be obtained first, before building. Click on drawing for printable Adobe .pdf file. Best wishes for your project.

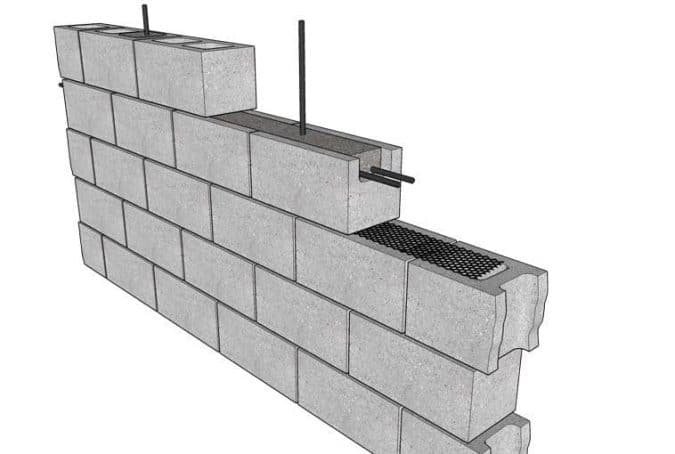

The top row of concrete blocks in a wall is constructed with 'bond beam' blocks. They come with knockout sections that are removed to allow laying horizontal rebar, as noted in drawing above. Depending upon engineering needs, bond beams can be specified for only the top course, to tie the vertical reinforcement of wall together, or one bond beam may be specified every fourth course when horizontal loads are encountered, as seen in a bermed wall. Bond beams can be used to construct lintel beams over openings for doorways or windows. 'Lintel blocks' can be used for single-course openings over windows and doorways, as seen on right above, where there is no vertical wall reinforcement. These U-shaped masonry units span gaps in walls between two vertical supports and space is filled with cement grout and horizontal rebar reinforcement.

This drawing illustrates a mortared block wall, but dry stack with surface bonding cement follows the same design. SBC just adds flexural strength and waterproofing to the wall. Note the wire mesh shown below the bond beam course. This wire mesh is used to prevent cement grout from flowing down into the lower block cells where vertical reinforcement is not placed. It saves on cement grout usage, leaving the hollow block cores empty of grout underneath the bond beam. Note the wire mesh is not placed in cores with vertical rebar where cells must be filled top-to-bottom. In an HTM design ALL cores are filled with cement grout (for structural strength) or sand (to increase thermal mass). Wire mesh, as pictured, is not used in a high thermal mass design where there is no reason to leave empty cores.

The roof structure, cmu rebar pattern, and backfill depth dictate ultimate wall engineering design. Generally, once your block walls have been surface bonded, hollow vertical cores (minimum one every four foot and alongside every opening) are filled with ready-mix concrete grout and a #5 rebar for an exceptionally strong heat storage mass. While possible in theory to rely upon SBC for flexural strength in excess of standard mortar cinder block wall construction, it is rare to see an engineer pursue that opportunity for a client and scale back rebar reinforcement. Likewise, while possible to avoid interior perpendicular walls and counterforts entirely, it is common practice to have one every ~18 foot when the roof structure does not provide adequate stability. Placed perpendicular to wall, roof beams act as retaining, but placed in other direction (parallel with wall) roof beams provide no wall support. Then the interior perpendicular walls both retain and provide bearing for parallel roof beams. Thus the ~18 foot mark for allowing 20 foot beams to span. Using roof trusses instead of beams has much the same, but lesser retaining effect, but only when opposite wall provides anchor for far end of truss. Sometimes you see short 'stub' block walls (counterforts) used to retain, with wood frame walls extended past counterforts on interior. Choice boils down to whether exterior wall is retaining backfill against structure. As always, consult with a qualified engineer.

You can purchase surface bonding material at any building supply center or at wholesale by the pallet from your block yard. We do not sell it and we are not the manufacturer. Our only interest in proposing SBC as a building method is to help our clients save some money while having the ability to construct their own home with their own hands. For an introduction to common dry stack cinder block construction techniques, please take this link: Quikrete® basic SBC Project Guide. This Quikwall manual is helpful for do-it-yourselfers considering a surface bonding cement project. The Quikrete manufacturer website for SBC is Quikrete.com or you can call their help line at 800-282-5828. Please note many other surface bonding cement manufacturers exist - check with your local block yard for details.

We do not sell any tools, but darbies, pool floats, magnesium hawks, arch raspers and bucket scoops can be found locally at construction tool suppliers. The same tools used for stucco work are used for surface bonding and parge coating of dry stack cinder block. The pool float is a hockey rink shaped applicator preferred by many to work the stucco or SBC into place. A foam handle is nice, if you keep your tools clean. Otherwise, composite handles are much easier to maintain. Magnesium blades are preferred by many for their ability to 'open pores' in the cement, versus sealing smooth and tight, as with steel blades. Magnesium has a nice feel, being rust proof and lightweight, yet thick and strong, making it preferred for hawks, floats and darbies. Arch rasps and bucket scoops are the other two images above - specialized tools for unique needs can cut labor time dramatically. The darby, for instance, is a two to four foot long two handed leveler that makes it possible to flat-level large surfaces quickly. Some darbies come with teeth for a sawing action as you level across the wall or floor. Others are flat with rounded lips along edge for sawing, smoothing and leveling more gently at the stucco, plaster or SBC.

Wood framing is most common for residential project given its ability to adapt to odd floor plan layouts. But cinder block has always been more popular with commercial buildings given its durability and longevity. That's what makes an HTM so economical and functionally sensible: this commercial-style block or poured-in-place concrete construction. HTM designs just add a coat of surface bonding cement to stop water transference and horizontal wing insulation for heating and cooling retention. Concrete and block are very low-tech LOCALLY available products without all the marketing fluff associated with SIPS, ICF pre-packaged insulated forms, special interlocking block shapes, and other costly trick methods. Reinventing the wheel is not necessary. Any local commercial contractor should be more than capable of working on the project. Here's hoping more websites, architects, engineers, and building departments get familiar with a worthy method. For a technique that has been around for centuries, it gets entirely too little attention.

Truly sustainable HTM passive solar home designs require a holistic approach, incorporating all core aspects for non-electric passively independent success. Picking and choosing HTM design components based solely on aesthetics will negatively affect passive solar function. Form follows function for best performance, economy, optimal health and personal comfort. We trust any hybrid HTM will function much better than a conventional home, but dropping a critical design element such as wing insulation or not collecting 'excess' solar energy will diminish overall passive solar performance. Our free HTM guidebook is maintained online for high thermal mass, sustainable, zero-energy, passive solar, green home building construction and design research. However, The Natural Home is not currently providing any paid engineering services or architectural design work. We cannot offer any local engineer or contractor trade referrals, other than noting stick-frame residential builders are rarely as HTM competent as commercial construction specialists. Best wishes for your project.

HTM Passive Solar eBook – Table of Contents

- introduction to high thermal mass pragmatic design, low-tech functions, and materials

- photo gallery is packed with images, commentary, and our free HTM Home Tour video

- dry stack surface bonding cement construction photos and some block layout sketches

- floor plans features several functional basic layouts and commentary on design choice

- roof detail chapter with T&G plank-style vented roof decking atop log purlin joist beams

- sun screens critical passive solar design component to create favorable micro-climates

- heat storage fiberglass water tanks are a low-tech way to moderate temperature swings

- earth tubing is simple passive technique to temper a household’s fresh air return intake

- solar orientation isn’t critical since HTM designs excel in hot or cold climates anywhere

- exterior fascia SBC coatings over EPS foam board insulation and sloped glazing details

- wing insulation and shallow footer, frost-protected perimeter foundation design choices

- planter beds are a central, functional component of greenhouse-style HTM construction

- links page is filled with a helpful selection of research references and relevant websites