SALE on heaviest-duty 5oz woven geotextile soil fabric

Off-season clearance pricing on our very best professional grade, lifetime-plus service, hydrophilic breathable treated, rot-proof polypropylene, extra heavy-duty 35 mil Woven 5 ounce geotextile septic leach field soil fabric. This superior, commercial duty soil drainage fabric is best choice for durability and longevity in French drains, leach fields, rockbeds, ditches, road and soil stabilization since it does not decompose. Never install cheap non-woven 'weed barrier' landscaping fabric. Our tightly Woven pure polypropylene soil drainage fabric is far superior for foundations, French drains, retaining walls, soil retention, paver underlayment, lining ditches, protecting rock beds, and septic system pipe-in-gravel or chamber or pressurized mound leach fields. Cheap non-woven weed barrier landscape fabrics are made with single strands of thread sealed together with heat or adhesives. Their flimsy non-woven bonding eventually tears apart as soil shifts. Non-woven fabrics degrade over time, allowing ever more sediment to pass through. Click for engineering specifications and MSDS sheet.

3 foot wide by...

30 foot = $33

60 foot = $46

90 foot = $63

120 foot = $78

250 foot = $129

4 foot wide by...

30 foot = $43

60 foot = $61

90 foot = $81

120 foot = $117

250 foot = $189

5 foot wide by...

30 foot = $52

60 foot = $74

90 foot = $99

120 foot = $144

250 foot = $229

6 foot wide by...

30 foot = $62

60 foot = $88

90 foot = $118

120 foot = $171

250 foot = $289

-

Heaviest-duty 5 ounce woven geotextile fabric, price includes UPS Ground shipping

Price range: $33.00 through $289.00 This product has multiple variants. The options may be chosen on the product page

We do not sell non-woven 'landscaping fabric', only the highest quality Woven geofabric. Beware of websites with very questionable statistics, such as 140 gallons per minute per square foot (140 gal/min/SF). The average bathroom shower water flow is about 2 gallons per minute... a flow rate of 140 gallons per minute is what you see coming out of a fire hydrant equipped with a 1-1/2 inch diameter hose. Considering a 1 inch rainfall is a little over 1/2 gallon per square foot, a realistic 12 gallon per square foot per minute flow rate (our geofabric) is more than adequate. Non-woven fabrics with high flow rates have larger openings which allow an unacceptable amount of sediment pass through. Once enough silt and soil passes through into the gravel layer, drainage slows dramatically and the system will prematurely fail.

We do not sell any lighter-weight woven geofabrics. The purported small increase in air movement is not worth the risk of fabric tearing and allowing soil to infiltrate. In practice, pipe-in-gravel septic leach fields and French drains are always vented at end of each pipe run, so you are not depending upon theoretical air movement through soil and fabric. Our professional grade, extra heavy-duty woven polypropylene geotextile fabric is 'hydrophilic treated' to allow air, water, and nutrients through its needle punched, multi-layer construction. For a quality, long-lasting project, avoid using cheap non-woven weed-barrier landscaping fabric, burlap (jute fiber fabric), thick layer of straw, or solid plastic sheeting. Natural fibers and non-woven weed barrier fabrics will mold and rot, eventually falling apart and allowing soil to migrate into the gravel layer. And plastic sheeting suffocates the soil, ultimately promoting anaerobic soil conditions, biomat formation, and mold issues.

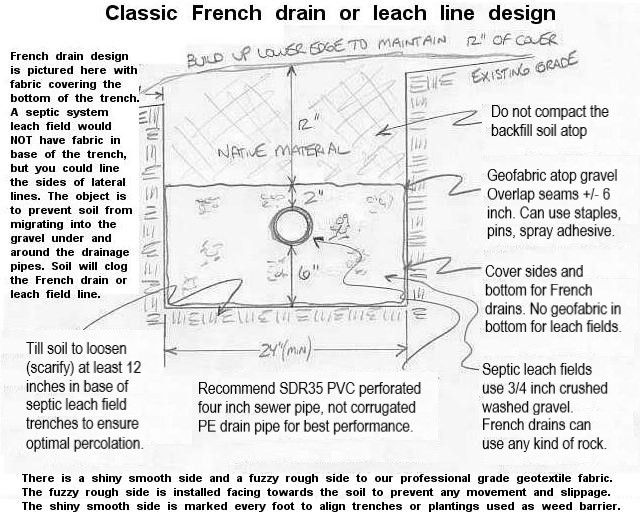

Our best professional-grade geofabric features a very functional ‘fuzzy’ side that lays down against the soil to prevent slippage, making it very easy to install on sloped ground. Fuzzy side facing soil allows fabric to trap and filter soil to better protect inner gravel layer and shiny side facing gravel in trench helps slough off particulates. Plus, the shiny smooth side has printed stripes every foot on center, full-length, for gauging trench elevations, rock fill levels, or lining up plants when used as a weed barrier. Proven effective, a superior forever performer, as compared to lesser ’20 year' landscape fabrics. Excess fabric can be overlapped in the middle or pushed down the trench side. Generally, there is no need for glue or landscaping pins on the overlap, since the weight of backfill atop will hold fabric in place. Ditches are easier to maintain with pavers atop, rather than river rock, since pavers can be lifted out to pull weeds sprouting upon the sediment in between.

French drain design & installation tips

French drains follow the same design as the septic leach field trench pictured above with exception of trench size and position of fabric and pipe. It is possible with a French drain to have less gravel under the pipe and a narrower trench (less than 24 inch wide), depending upon anticipated flow. French drains function as an underground 'ditch' that takes effluent to a drywell leach pit kit or to a sump basin with pump for disposal or to 'daylight' with exposure atop the ground. Normally, a perimeter French drain is located immediately adjacent to the building foundation, under the eaves, so surface runoff is not an issue. Excavate down below the level of the base of the footer for best overall effect. The object is lower the groundwater level and prevent wicking moisture into the foundation as much as possible. While the foundation is exposed, pressure spray sub-grade walls, allow to dry completely, and then apply several mop-coats of waterproofing. Or if you have it in the budget, best practice is to apply bithumen roofing underlayment to completely seal sub-grade basement walls. Always 'prime' the wall first with compatible coating or a single mop-coat of foundation sealer prior to applying the bithumen roofing underlayment. Chances are it will not pull away from the concrete after being backfilled, but always best to prime the foundation wall first.

If you wish to grow a grass yard back atop a French drain, it will require at least one foot of well-fertilized balanced 'potting soil' mixture atop the geofabric. Avoid fescues and other deep-rooting grasses or bushes as they may intrude on the perforated pipe, causing clogging and eventual failure. Plant shallow-rooting low-water grasses for best success. Note that one should avoid capping a French drain with soil and grass when capturing surface runoff is desired. Best to bring gravel up to the surface and 'cap' with pavers or landscaping gravel or mulch when you wish to percolate surface water down into a French drain. Exposed gravel 'ditches' are best practice for French drains in poorly percolating soils. For French drains in heavy clay soil, rainwater is not percolating very much from the sides or bottom of the ditch, so there is no need to loosen or scarify soil in base and sides, as seen when percolating water into the soil with a septic system leach field.

Ideally, the French drain (ditch) slopes at least 1/8 inch per foot so it is always dry between surges, but even when the ditch is perfectly level, water will flow towards the drywell leach pit or daylight exit as the ditch fills up with water. Water moves through the gravel in base of 'ditch', not necessarily through the pipe. As the water level rises in a storm surge, it comes up through the holes in bottom of perforated pipe and quickly flows out unimpeded. Rather than just one exit from the perimeter foundation drain, it is best to flow away from two opposing corners, or every corner on larger buildings. Be sure to 'cage' the pipe where it exits to 'daylight' or drywell leach pit with heavy-gauge welded wire mesh to discourage rodents from creating blockages. Installing cleanouts every twenty to fifty feet will allow inspection and jetting should you have a blockage.

In practice, pinning fabric to sides of trench with landscaping pin staples is not practical, especially at depth. As you fill the ditch with gravel, staples (or pointed wood lathe stakes) can pull out of the soil. Common practice is to use 'shoring benches' for safety and accuracy when filling deeper trenches with gravel. To make your own shoring benches, cut 2by6 lumber and glue and screw together in an 'H' shape (double bar across width) slightly smaller than the width of trench. Build four or five shoring benches and you can quickly move them down the trench as you fill it with gravel. Pipe can be passed underneath the 'H' bar. Sides are marked for pipe elevation and depth of gravel. Set nails at finish gravel depth and a string line can be pulled for easy, accurate final grade. In practice, it is usually easier to install two pieces of fabric and overlap rather than encircling the gravel and pipe with a single piece of geofabric. Seams can be pinned, stapled, or 3M spray-glued together, but with at least four to six inches of overlap, the weight of soil atop will keep seams from moving after it settles.

Roof gutter downspout installations always benefit from large diameter solid pipe standpipe. With gutter and downspout rain water disposal, a two (2) inch rainfall is 1.25 gallons per square foot of roof (1 gallon is 231 cubic inches) 1 cubic foot is 1728 cubic inches or 7.48 gallons. A 1000 square foot roof generates 1250 gallons of water in a two inch rainfall, so you have to plan for air (room) around gutter downspout as it enters standpipe. Best practice is a 6 inch diameter standpipe at ground level for a 2x3 downspout when extreme amounts of water are anticipated. Otherwise, the standpipe in ground will 'burp' and send gutters spilling onto the foundation. Always best to send downspout water at least 10 feet away from foundation.

septic leach fields & chamber systems

Avoid using single-wall corrugated PE drainage pipe in a French drain or septic system. For longevity and performance, always use perforated four inch PVC pipe and geotextile fabric around a gravel layer. Best to use SDR35 (ASTM D-3034) or thin wall ASTM D-2729 perforated 4 inch PVC sewer drain pipe with two rows of 1/2 inch diameter holes facing downwards. Or the triple-wall corrugated N-12 pipe with smooth interior wall which conforms to D-2729 standard. Geotextile fabric keeps soil from migrating into gravel layer around pipe. Never use 'filter sock wraps' immediately around drainage pipe since they impede flow as a trade-off to preventing much smaller holes on corrugated pipe from clogging. Filter sock wrap is not necessary with perforated four inch PVC pipe that has much larger 1/2 inch diameter holes with a much faster flow rate.

The drawing above is standard practice septic system pipe-in-gravel leach fields except geofabric is not placed on the bottom of leach field trenches. All measurements are bare minimum specifications. Leach field trench runs may well be required to be wider and taller, depending upon local building codes. Three foot wide trenches are common practice. Always check first with county officials before proceeding with project. Washed crushed gravel 3/4 inch nominal up to 1-1/2 inch is traditionally used depending upon local building code. Your local quarry may refer to septic system leach field gravel as a #5 or a #57. The #5 translates as "crushed stones 1 inch or less". Sometimes, they don't bother to "wash" it to remove sand and fines. The #57 is a little more specific at +/- 3/4 inch. You can use any size and type of gravel you wish for a French drain, but septic systems benefit from crushed gravel of this size for greater surface area for optimal treatment of waste effluent. Septic and greywater disposal lateral lines and leach pits DO NOT install geotextile fabric on the bottom, underneath gravel, where it would accumulate bio-mat and eventually block percolation of the wastewater. Fabric is sometimes not placed on the side of wider leach field trenches or large 'beds' to make installation easier, but it is highly recommended on the sides to prevent soil from entering the gravel. Note trenches and interior perforated pipe are always installed level in a septic leach field. There is no slope to the perforated pipe in a septic leach field trench, as sometimes seen in a French drain.

Especially in poorly percolating clay soils, protect leach field longevity by over-excavating trenches and scarifying the soil on sides and bottom. Dig at least one foot past where the base of septic system leach field trench is located and loosen 'scarify' the soil by deeply raking. In extremely poor soils, best practice is to rake 3/4 inch nominal crushed washed aggregate into the scarified area. Then add your gravel atop for the septic system leach field, whether it is perforated pipe in gravel or Infiltrator chamber septic leach field systems. Geofabric can be installed above Infiltrator chambers to prevent migration of surrounding soils from entering. Recommended in wet and potential flooding areas with sandy or silty soil. If you wish to grow a grass yard back atop, it will require at least one foot of well-fertilized balanced 'potting soil' mixture atop the geofabric. Avoid fescues and other deep-rooting grasses or bushes atop a leach field as they may intrude on the perforated pipe, causing clogging and eventual failure. Plant shallow-rooting low-water grasses for best success. Please read the Infiltrator chamber septic leach field system chapter for detailed design tips and tricks that apply equally well to perforated pipe-in-gravel leach field construction.

"Are we allowed to install this geotextile soil fabric on our property" is not a question we can answer for you. We have been providing much the same professional-grade geotextile fabric for going on thirty years now, but we do not follow all of the constantly changing city, county, and state building regulations. Unfortunately, with over 3000 counties in the United States, regulations changing from year-to-year, and interpretations of those rules varying from one inspector to another, it's never possible to say for certain 'what is allowed' locally. We provide free consultation after the sale on installation procedures, system design improvements, and operational issues, but we do not provide any soil testing, on-site services, 'stamped' engineered plans, or 'advanced treatment' systems. This professional grade geotextile polypropylene fabric has proven itself over time to be a superior performer, as compared to other '20+ year landscaping fabrics'. Here is our geotextile soil fabric engineering specifications and material MSDS sheet.

planter boxes, retaining walls, stalls & xeriscaping

Wood and concrete planter boxes benefit from our heavy-duty woven geotextile soil filter fabric. Polypropylene will never rot in wet soil or break down when not exposed to direct sunlight. LIfetime service in any planter box. For a more natural fiber, you can try several layers of burlap, but it will rot and fails to slow root infiltration. Ornamental planterbeds line the bottom and insides with pond liner or bitumen roofing underlayment to render it waterproof, then drill 3/8 inch diameter weep holes in corners and every foot on center, then line the bottom of planterbox with geofabric, add a couple of inches of nominal 1/2 inch gravel in base for drainage, and then install geofabric, continuous from bottom and running up all four sides. Staple the geofabric in place with fuzzy side facing the soil. When growing vegetables, you may wish to avoid bitumen underlayment waterproofing. Multiple layers of linseed oil can be used for a more natural approach. For an organic planterbed, do not use 'boiled' linseed oil since it contains metallic dryers to accelerate curing. Boiled linseed oil is basically raw linseed oil plus 'Japan Drier' for polymerization, oxididation, and hardening of the oil coat. Japan drier is lead-free, but with 97% Naphta and 3% Cobalt compounds. If you are concerned about tree root penetration into the bottom of a raised planterbed, use an HDPE or EPDM pond liner. Geotextile fabric of any sort will not completely prevent tree root infiltration.

Retaining walls, mulch and rock beds have much greater longevity with our commercial-duty geofabric. Larger boulders will not tear through this durable woven material and pavers will not rip and tear woven fabric like it will non-woven weed barrier cloth. Lining the back side of retaining walls with geofabric is standard practice to hold-back soil and limit shifting during heavy rainfalls. Always best practice to install a French drain at the bottom of any retaining wall to prevent water from accumulating, especially in cold climates where frost heaving can damage brick, block and pavers along the bottom. When placed underneath mulch and rock beds, geofabric ensures weed-free xeriscaping by making it much easier to pull weeds as they spring up between boulders, while still allowing water to pass through readily.

If you are designing a rockbed or xeriscaped yard, always plan ahead for water runoff to avoid ponding. Use a transit to mound small rockbeds and carve 'swales' (very shallow ditches) in the underlying soil to carry rainwater away from larger xeriscaping yards. While the geofabric will percolate adequately, your underlying soil may be relatively non-porous. This is especially true when installing a six to eight layer of 'road base' or mixed crushed gravel beneath your decorative rockbed. 'Road base' includes a percentage of clay to encourage the crushed gravel mixture to bind together (like a gravel road). Projects atop silty, sandy, or clay soils may require two layers of geofabric. One layer atop the existing porous soil to prevent gravel from sinking into the unstable underlying ground and a second layer atop before installing your final layer of decorative rock. Even without machine compaction, the clay content typical in 'true road base' will solidly bind together over time. River rock will have a fluid feel (less solid) when walking atop. Discuss gravel options with your quarry to ensure you get what you need. Their definition of 'road base' versus 'mixed crushed gravel' can vary dramatically.

Horse stalls, animal pens, walkways, barn and stable floors can be kept mud-free in any soil type. Excacate at least eight to ten inches before installing at least one layer of geofabric, with at least one foot overlaps. Backfill with road base or crushed gravel mixture, as noted above. A second layer of geofabric atop is needed for a final layer of pine shavings or straw bedding. This keeps your roadbase from being 'polluted' with mud and mulch, but periodically needs replaced.

Commercial duty 0.157" diameter 4mm steel pins

8 gauge wire 15% to 40% thicker than 9 or 11 gauge

2 inch wide which is over 25% larger than residential

8 inch long with chisel ends for ease of installation

You can step on extra-wide pins with your boot

New product ... no shopping cart or pricing yet

They will be sold in #500, #250, #125 count boxes

Shipped via USPS Priority Mail from Colorado