Infiltrator Quick4 leach field chambers - Colorado only

Infiltrator Quick4 Plus septic leach field chamber arches interlock for much greater capacity (surge volume) than perforated pipe-in-gravel septic drain fields. Colorado building code regulations commonly provide up to 30% leach field size reduction because sewage is provided with a lot more oxygen and much greater retention times. Septic system longevity is ensured with immunity to root infiltration problems and less bio-mat formation. We do not sell the cheaper, lightweight ARC chambers or any of those other inferior off-brands. We only sell the heaviest-duty Infiltrator Quick4 Plus chambers which have an H-10 load rating (16,000 pound single axle) given at least one foot of machine compacted cover. You should never drive over any leach field, but Plus series chambers will handle occasional traffic when driven across like train tracks. We have not sold other brands for many years because Infiltrator Quick4 Plus chambers have proven to be the best.

Please email service@thenaturalhome.com with any product questions or design concerns.

For over 30 years, we have been providing FREE consultation to our clients. Engineered plans are traditionally bare minimum acceptable standards, never mentioning any optional parts. Inspectors and engineers very rarely, if ever, discuss design choices that will improve performance and safety, increase longevity, expedite construction, and prepare for future repairs. Unlike other plumbing supply firms, we take an interest in your project, providing our clients with free consultation. We encourage you to mail a copy of your site plan for free review with purchase of an Infiltrator septic system. Please note The Natural Home is not an engineering firm; we do not provide any engineering services.

Minimum order delivery is FREE by company truck within about a 50 mile radius of central Denver. North to Fort Collins and Greeley, South to Franktown and Monument, East to Deer Trail and Tampa, West to Georgetown and Silver Plume, and SouthWest to Bailey and Conifer. Delivery a few miles outside of this radius may be possible for a fee. We can normally schedule an AM or PM delivery given at least three days advance notice, weather permitting. Designated receiver must be on site and waiting to help unload merchandise by hand. Or you can will-call pick up in person at our central Denver area warehouse with a pre-paid order. Warehouse will-call hours are 7:30 AM to 4 PM on Monday through Thursday and 7:30 AM to 2 PM on Friday. Payment at the yard is not possible to arrange. Infiltrator products are not shipped outside of Colorado. Outside of Colorado, contact InfiltratorWater.com or info@infiltratorwater.com or 800-221-4436.

Email service@thenaturalhome.com with system parts list

for an invoice with VISA or MasterCard personal payment link

*5% Discount for bank wire, cashier check, postal money order

Infiltrator tanks and Quick4 chambers are always kept in stock

Infiltrator Quick4 Standard chamber quantity pricing below:

Quick4 Plus Standard quantity pricing is above

12" tall by 34" wide by 52" (48" long assembled)

$30 ($28.50*) 'All-In-One 12' multiport endcaps

Quick4 Equalizer 36 are $3 less than Standard

12" tall by 22" wide by 52" (48" long assembled)

$27 ($25.65*) each Equalizer multiport endcaps

Quick4 Plus Low-Profile $2 less than Standard

8" tall by 34" wide by 52" (48" long assembled)

$27 ($25.65*) each Low-Profile multiport endcaps

Quick4 Plus 'High-Capacity' HC are $17 more

14" tall by 34" wide by 52" (48" long assembled)

Only 15% (7 gallons) additional storage capacity

Quick4 H-20 Rated HC cost over twice Standard

16" tall by 34" wide by 52" (48" long assembled)

Special order and can take weeks to manufacture

H-20 HC are only used in roads and parking areas

$209 for 4 foot by 250 foot 5 oz woven geofabric

Drape atop chambers to stop sand & silt infiltration

$49 ($46.55*) 7-hole Tuf-Tite distribution box

Free plugs & seals - specify SDR35 or Sch40 pipe

$22 ($20.90*) each for 6" tall D-box risers

May not be required, but smart to take lid to grade

$2 ($1.90*) each for D-box speed levelers

Even distribution and allows shut-off to select runs

$59 ($56.05*) 9-hole Tuf-Tite distribution box

Free plugs & seals - specify SDR35 or Sch40 pipe

$53 (*$50.35) each for 12 inch tall Tuf-Tite risers

$30 (*$28.50) each for 6 inch tall Tuf-Tite risers

$32 (*$30.40) each for green domed riser lids

$239 (*$227.05) 10-hole Rhino distribution box

24 inch diameter with Ten (10) potential openings

Four (4) Free 3001-SN seals fit 2", 3" or 4" pipe

Seals require 5-1/8" (130mm) hole saw to install

Here's a 5-1/8 inch hole saw on Amazon for $14

$7 (*$6.65) each for additional 3001-SN seals

$32 (*$30.40) each for 2 inch tall Rhino risers

$53 (*$50.35) each for 6 inch tall Rhino risers

$88 (*$83.60) each for 12 inch tall Rhino riser

$107 ($101.65*) Flow director ships via UPS

Splits effluent 50/50 or 100% in one direction

Pipe and fittings are less expensive to purchase at HomeDepot or Lowes

Pumps, floats, alarms, and control panels are also cheaper to buy online

If you can't find any special parts, we can source them with system purchase

Quick4 Plus Series is the updated Infiltrator chamber design with solid support legs that also serve as distribution pipe mounting brackets. We do not sell the much less sturdy Arc Series. Standard chambers are 12 inch tall by 34 inch wide for installation in a 36 inch wide trench and offer advanced curved run capability with Contour Swivel Connection™ that permits turns up to 10 degrees, right or left. Standard 12 inch tall chambers are 52 inch long (48 inch net) for a 47 gallon initial surge capacity. Infiltrator Quick4 Plus Standard chambers weigh about 13 pounds each and a full pallet of 85 chambers is 7 foot 6 inch tall. With a base of over 12 square feet, they stack very stable in the bed of a truck without a pallet, but they can be 'palletized'. Just ask when you arrive for will-call and staff will band them up. But with or without banding, it is necessary to secure your load. Suggest using at least a couple of 2 inch wide DOT-rated ratchet tie-downs to satisfy CSP.

All installation tips detailed here apply equally to perforated pipe-in-gravel leach fields. With 64 very independent counties in Colorado, each with their own unique set of regulations, and an infinite variety of site and soil conditions, we cannot predict what will be required. Always check with your building department to confirm local regulations prior to planning any septic or greywater system to confirm what is required for your property. The Natural Home is not an engineering firm; we do not provide any engineering services, soil testing or on-site work.

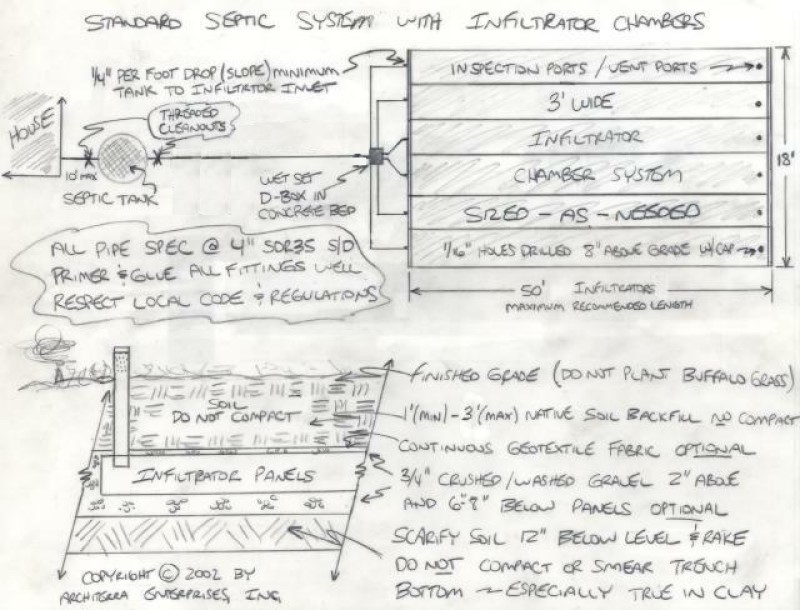

Installation involves digging a series of three foot wide trenches, or single large rectangular 'bed', connecting the Infiltrator chambers and then back-filling with existing soil. As a general rule, trenches 'fingers' should be no longer than fifty feet (12 or 13 Infiltrators long) for best function and most even effluent distribution. Unless you are installing as a "bed" system (where the chambers are right next to each other), leave at least six feet of undisturbed soil between fingers. In practice, this six feet of undisturbed soil between trenches becomes eight feet or more since you don't want to compact the soil above the Infiltrators; one should allow at least the width of the backhoe between trenches. And don't forget to loosen the soil twelve inches below bottom of the trench (scarify) before installing the Infiltrators leach chambers. The worst mistake you can make is to compact (smear) the soil in bottom of a leach field trench. You want to be sure to loosen 'scarify' the soil to allow for proper percolation of effluent. No gravel is needed, but gravel is always an upgrade option to aid treatment and longevity in any soil. Geotextile soil fabric atop chambers is not absolutely necessary, but in sandy or silty soil, geofabric is recommended for the sake of longevity to keep flooding soil from migrating into the chambers.

Infiltrator Plus series chambers are far superior to pipe-in-gravel in every aspect: smaller leach field size due to optimal percolation, large 47 gallon storage capacity per chamber, root infiltration protection for long term viability, and resistance to traffic with 16,000 pounds per axle load rating, given at least one foot of cover. There is an H-20 traffic load rated Infiltrator chamber available that can handle 32,000 pounds per axle with at least 18 inches of compacted 'road base' soil above. However, driving over the top of any leach field is not recommended and may not be allowed by local building codes. When traffic is necessary, always drive perpendicular from the side, not down the length or even a load-rated chamber could collapse. Traffic rating is per axle, not per tire, assuming both tires hit at the same time. Maximum acceptable burial depth for Quick4 Plus chambers is determined by local site, soil, and groundwater conditions. Local building code and/or engineer dictates the maximum allowable depth, usually at about 3 feet to the top of the chamber. The manufacturer does not address maximum engineering depth other than to suggest no more than 8 feet to the top of the chamber.

estimating number of chambers and field design

There is no accurate method to estimate how many Infiltrator chambers are required without digging test pits in area of leach field. A percolation test performed at depth of leach field can approximate soil absorption rate, but only a test pit at least six feet deep will confirm soil composition beneath the leach field, ensuring proper waste treatment is possible in the critical first three feet. Number of chambers is determined with soil/usage equation supplied by local building department which varies from county-to-county, let alone state-to-state. That equation typically takes into account '1.5 engineering factor' which includes 50% extra for long-term viability. A very general 'rule-of-thumb' minimum size is "one square foot per gallon per day" minus up to a 30% reduction for using chambers instead of perforated pipe-in-gravel leach field. But that could be way off, depending upon actual soil percolation rate and estimate of daily usage. Bare minimum usage rate to estimate with is 100 gallons per person per day. Therefore the building department often uses 200 gallons per bedroom per day when sizing residential systems. Each chamber is 12 square feet of base area and 8 square feet of sidewall area. For instance: 2 bedroom home may be calculated locally as 2 x 200 = 400 x 1.5 = 600 gallons per day usage. If you are given credit for sidewall percolation from trench chambers, that is 600 divided by 20 = 30 chambers in well percolating soils. More conservative approach (less well percolating soils) would be to estimate using only the base area of trench: 600 divided by 12 = 50 chambers. There is a huge difference between what is 'possible' to percolate daily and what is best for sewage treatment to prevent contamination of groundwater. The larger the leach field, the better the treatment of wastewater. This is a critical factor when there is a well drilled within 200 feet of leach field location and/or you have seasonally high groundwater present that could prevent proper treatment of sewage. Best practice is to limit trench lengths to about 50 foot (12 to 13 four foot long chambers) for full trench saturation and best treatment of effluent.

Strip all topsoil from atop the tank, pipe, and leach field area and stockpile for revegetation later. Best practice is to return all soil, 'mounding' atop the leach field to encourage rain to drain away from the leach field area. Keep all vehicles OFF the absorption field area. After construction, protect all components from livestock and vehicle traffic to avoid soil compaction. Do not use the drainage area for snow storage.

Geotextile fabric & liners for perforated pipe leach fields and mound systems

Fabric delivery is only available with purchase of an Infiltrator system. Not shipped separately.

Please note that all Infiltrator and geotextile fabric prices are subject to change without notice.

$157 for 6 foot by 300 foot (200 sq yd) of 2 ounce sq yd non-woven polypropylene

$257 for 10 foot by 300 foot (333 sq yd) of 2 ounce sq yd non-woven polypropylene

$307 for 12 foot by 300 foot (400 sq yd) of 2 ounce sq yd non-woven polypropylene

$769 for 12 foot 6 inch by 360 foot (500 sq yd) of 4.2 ounce sq yd non-woven 'Mirafi'

$929 for 15 foot wide by 360 foot (600 sq yd) of 4.2 ounce sq yd non-woven 'Mirafi'

$477 for 6.35 foot by 100 foot roll (635 sq ft) of 30 mil PVC mound liner membrane

do-it-yourself septic leach field design tips and rules of thumb

* Strip all topsoil from atop components and stockpile for revegetation later

* Return all soil, mounding atop leach field to encourage rain to drain away

* Keep all livestock, vehicles, and snow storage OFF tank and leach field

* Limit field runs (rows) to 12 or 13 chambers for about 50 feet total length

* Always bring effluent pipe in top of chamber end cap, never into the bottom

* Install large granite or durable ceramic tile underneath inlet for splash plate

* Always ventilate the ends of every leach field pipe run or set of chambers

* Loosen 'scarify' soil at least one foot in base of trench before backfilling

* Add gravel into base of trench and atop chambers to improve longevity

* Geotextile fabric prevents soil intrusion into gravel from above & sides

* Never install geofabric in the bottom of any trench or septic leach field

* Septic tank up to 10 feet away and leach fields 20+ feet from foundation

* Leach field, especially pipe-in-gravel, should be 20+ feet away from trees

* Never plant bushes or deep-rooting fescue, dichondra, brome, or rye atop

* Never drive over a septic tank or leach field - chambers perpendicular only

All 'gravel-less' leach field chamber system brands function by the same set of physical limitations, regardless of marketing claims. Installation tips are not required, but there are always 'good, better, best' methods of approaching any construction project. 'Good enough' with chambers is digging a level trench and backfilling atop with native soil. 'Better' is to scarify (loosen and rake) the soil in base of trench to a depth of at least one foot before installing chambers. 'Best practice' is adding at least 6 inches of crushed washed 3/4 inch nominal gravel atop scarified soil to ensure long-term percolation and best sewage treatment. Your local quarry may refer to septic system leach field gravel as a #5 or a #57. The #5 translates as "crushed stones 1 inch or less". Sometimes, they don't bother to "wash" it to remove sand and fines. The #57 is a little more specific at +/- 3/4 inch size. You can use any size and type of gravel you wish for a French drain, but septic systems benefit from crushed gravel of this size for greater surface area for optimal treatment of waste effluent.

Some engineers go one step further and lay 2 inch diameter perforated pressurized distribution pipe in the top of chambers with 1/4 inch diameter holes every 2 foot facing upwards to ensure equal effluent introduction throughout the trench. This only works with a lift station 'dosing tank' to send a couple hundred gallons of effluent out at one time. Non-pressurized (no pump or dosing tank) systems do not benefit from distribution pipe since the larger 1/2 inch diameter holes must face downwards and effluent rarely reaches the end. When specified, non-pressurized systems strap 4 inch perforated pipe either side of the structural columns found on Quick4 Plus chambers. Do not run distribution pipe along the base of the trench since that area can be flooded at times should percolation rate be slow. Several inches of gravel atop chambers with a layer of geotextile fabric on top and sides is common practice in sandy or silty soils. Best practice is to limit trench lengths to about 50 foot (12 to 13 four foot long chambers) for full trench saturation and best treatment of effluent.

venting the end chamber of every chamber run

Always vent the ends of each chamber run to ensure healthy air flow through system. Inspection port at end of each run must be drilled with holes to provide venting. Air is pulled through the chambers and out the plumbing vent atop roof of house. Fresh air and healthy soil are critical for long-term viability of leach fields. Standard ventilation specification is 1/8" diameter holes drilled at least one every square inch for at least eight inches above finish grade and capped. Larger holes are discouraged to prevent insects from nesting in the vent port. By allowing air to draft through chambers, you provide oxygen to an otherwise sealed cavity. Encouraging aerobic (oxygen-based) bacteria to prosper inside the leach field helps keep soil healthy and limits the growth of bio-mat anaerobic (no-oxygen) build-up from septic effluent particulates. Bio-mat formation is what eventually clogs soil, stops percolation, and causes leach fields to fail.

Take with a grain of salt, any claims of "superior" systems such as the Eljen GSF 'geotextile sand filter' with passive advanced treatment technology. In our experience, clients very rarely concern themselves with more effective treatment of wastewater, but rather the ultimate longevity of their leach field. Chamber systems have the major advantage of a very large surge volume, something niche systems like the Eljen GSF geotextile sand filter do not offer. In the long run, having a larger retention area for daily surge potential is what keeps a leach field from failing, not shiny bells and whistles. We recommend installing the largest septic tank possible for optimal settling and filtration before wastewater reaches the leach field rather than investing in wastewater treatment gimmicks. We cannot recommend Easy Flow 'engineered drain systems' which combine corrugated slotted pipe wrapped with geotextile fabric and expanded polystyrene aggregate (packing peanuts) held in place with a netting wrap. These are fine for a French drain, but not when used in a septic system leach field. Easy Flow longevity is terrible given the accumulation of bio-mat inside the pipe and against the geofabric wrapping. They are an absolute nightmare should the contaminated pipe and packing peanuts ever have to be removed. Worst job ever.

never use ANY additives or enzyme digesters

Properly sized two compartment septic tanks operate just fine without potentially dangerous additives. Breaking down fats and solids in the septic tank with digestive enzymes simply allows these now much smaller particles to pass through the septic filter where they reunite in the leach field, forming a dense bio-mat. The FDA has never approved any additives; none are considered safe or effective. You don't want these additives finding their way into the groundwater where they can be used for irrigation and drinking. Leach field distance from the wellhead (100 to 200 feet) is no guarantee of safety, it's just an arbitrary number locally assigned to allow residential construction on smaller half acre lots. Lateral water (sewage effluent) movement underground is extremely unpredictable at certain times of the year and will easily contaminate your well. Any chemical (or enzyme) which digests sewage should frighten a reasonable person to allow in their drinking or irrigation water.

bed all leach field pipe in plenty of gravel

All pipes must be well-bedded in at least six inches of +/- 3/4 inch gravel to avoid frost issues or soil settling and heaving pipe off-level. Best practice is first connection (joint) at effluent pipe coming out of foundation be made with rubber boot coupler. Common mistake is solvent welding that first joint with a hard fitting and not bedding pipe. Should the newly installed pipe run settle, a rubber boot coupler will adapt, unlike solvent welded joint. Pipe from foundation to septic tank slopes maximum of 1/4 inch per foot. Too steep of slope and water will bypass solid waste in the pipe, eventually clogging it. Slope minimum 1/8 inch per foot from septic tank to distribution box and leach field. Much steeper is possible, but best to level-off prior to the distribution box or the turbidity will affect equal splitting to runs. Use lots of purple primer on all pipe joints and splash it around to allow inspector to clearly see everything was properly primed before solvent welding.

Four inch diameter sewer pipe comes directly from cleanout, immediately adjacent foundation, to the septic tank. No bends should be installed between house and septic tank or toilet waste may settle in the line and eventually block flow. After the septic tank, sewer pipe can make bends as need be. Just maintain 1/8 to 1/4 inch per foot slope until the septic tank. Greater slope than 1/4 inch per foot may allow water to flow around toilet waste, allowing it to settle and block flow. Less than 1/8 inch drop per foot and you may leave flat sections or dips that can freeze. When designing site plan, you are not limited to coming in one end of tank and out the opposite end. Infiltrator tanks can be plumbed from three directions on both ends.

Critical detail is to bed all pipe, fittings, and distribution boxes well in at least six inches of gravel to ensure level is maintained and frost is not an issue. Best practice is to 'wet-set' distribution box atop a bag or three of Quikrete to ensure level is maintained. Wet-set refers to pouring dry concrete mix under and around and then wetting it with water. You can pre-mix the concrete or set with minimal water in the field with 'fence post' dry mix. Fill the bottom of D-box with water up to hole openings to give it some weight. Water will exit all outlet holes evenly when box is perfectly level. Bringing lid up to near the surface with D-Box risers will allow use of Speed Levelers to dial-in accurate distribution. Rotating speed levelers upside down allows individual runs to go fallow and dry out seasonally to help protect longevity.

Concerning the use of Sch40, SDR35, or ASTM 3034 pipe in septic systems, SDR35 'sewer, drain, vent' pipe with 3034 fittings is adequate for wastewater systems outside the home foundation. Sch40 thick wall pipe is only required for pressurized water systems. Sch40 might help should you ever drive over the system, but one should never ever drive over any pipe. At the very least, you may create a dip in the line and block flow. Should you be forced to drive over a section of pipe, always 'sleeve' the four inch pipe inside an outer six inch Sch40, or thicker, galvanized metal pipe.

steep slope leach field design & installation

To be properly engineered, steep slope installations require a professional soil survey and groundwater impact study. While there is plenty of literature online, the list of specific site variables is virtually endless, so you run the risk of not asking the right question(s). For instance, soil erosion may be a critical issue never considered. In practice, effluent needs to percolate vertically through at least three feet of amenable soil before it enters the groundwater. This level of sewage filtration is considered the bare minimum acceptable in most of the country. Sand mounds and advanced treatment systems are commonly specified when either the soil is not amenable or the site is too steep. Local building codes always dictate.

The main concern on a steep slope is preventing effluent from traveling laterally down the hill, either above or just beneath the surface. In a worst case scenario, effluent is unable to percolate vertically, for proper waste treatment, and ends up becoming surface runoff, flowing directly into an adjacent waterway. The bottom of any slope is by definition a 'seasonal waterway' during periods of heavy rain or spring snow melt. Be very aware of neighbors' well head locations.

Physically, you start by excavating 'benches' (terraces) that are level from one end to the other. Then, soil allowing, you cut your three foot wide trenches (standard Quick4) contouring them to the hillside. Key is having a level trench to install chambers. Quick4 can be curved to adapt to a contured hillside, so the trenches do not have to be straight, just level. You often end up with a design that benefits from 'center feeding', which is bringing effluent into the middle of a run, not the end. Here is an introductory article from Infiltrator's Onsite Installer magazine with some handy illustrations.

Engineers seldom consider the aesthetics of a steep slope layout. Given overall dimensions, these terraces are a commanding landscape focus. You can create wet-sand scale models to test alternatives. Talented survey crew, solid geometry, and quality woven geofabric are keys. Expanding the overall width/depth of your 'benches' will greatly increase terrace square footage with minimal machine time. Plus, wider benches provide safer perches for your excavator.

"Are we allowed to install this septic system on our property" or "how many chambers do we need" are not questions we can answer for you. We have been providing septic system parts for over thirty years now, but we do not follow constantly changing city, county, and state building regulations. Unfortunately, with over 3000 counties in the United States, regulations changing from year-to-year, and interpretations of those rules varying from one inspector to another (and one engineer to the next), it's never possible to be certain 'what is allowed' locally. We encourage clients to mail copies of their septic system plans for our free review with purchase of a system. But understand that The Natural Home is not an engineering firm; we do not provide any engineering services, soil testing or on-site work.