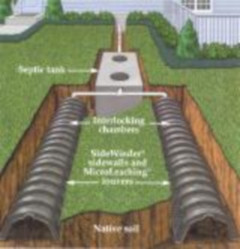

Infiltrator septic tanks, leach field chambers, and geofabric

The wastewater your home produces is called 'effluent' and consists of blackwater (toilet and garbage disposal waste) and greywater (shower, sink and laundry waste). Effluent flows directly from your household plumbing into a watertight, underground, two compartment septic tank. Solid waste settles into a sludge layer on the bottom and fats float to the top of the first compartment. Between these two scum layers is a zone of clarified liquid effluent which is internally piped to the second compartment of the septic tank for additional settling. As incoming sewage from the house fills first compartment, clarified liquids are forced to leave the second chamber of the septic tank and flow out to the leach field or leach pit. The typical leach field is a series of chambers or rock filled trenches where effluent is further treated as it slowly percolates through the soil.

If allowed by your local building department, it is always best practice to divert household greywater to a separate leaching area. Greywater from washing machine, sinks and showers contains soaps designed to kill bacteria (clean and disinfect things) and thus discourage optimal septic tank function. You want to encourage helpful good bacteria (digesting anaerobic cultures) to grow in your septic tank and organically treat the sewage waste, not kill helpful bacteria with detergent laden graywater. A leach pit is a deeper, larger hole filled with rock for disposing of wastewater in a smaller footprint. Not as effective for sewage treatment as a leach field, where sewage percolates slowly over a larger area. Leach pits are an alternative for smaller properties that do not have room for a leach field and locations without high seasonal ground water.

Please email service@thenaturalhome.com with any questions or concerns.

Septic system parts ship free via UPS Ground to all 48 contiguous states. Website products with an 'Add to Cart' button generally leave Colorado by the next business day.

Colorado Delivery Only - Infiltrator® septic tank kits with consultation

Infiltrator IM series septic tank pricing, manuals, design tips, and specification sheets. Plastic septic tanks never rust or crack due to ground heaving. Easily moved around by two people, saving money on crane work. Rent a backhoe and install your own septic system! Our Infiltrator injection molded poly tanks are UPC listed for permit approval ease and dry burial up to four feet deep. Infiltrator® heavy-duty plastic septic tanks have proven far superior to other plastic tank brands and preferrable to concrete septic tanks, especially in the high country.

Infiltrator septic tank pricing and installation tips & tricks

Septic tank installation is relatively straight-forward, but even seasoned professionals can get too mired in how they've always done it to realize there are better ways to approach any project. We are here to help our clients every step of the way, doing our best to ensure you don't make that one critical mistake, like not using risers or not venting your leach field.

Clients are encouraged to submit their site plan and planned usage for free review after purchasing one of our septic systems.

Colorado Delivery Only - Infiltrator® chamber leach fields with consultation

Many people don't understand that perforated pipe in a gravel bed is NOT the best choice for a long-lasting, durable septic system. Infiltrator® chamber leach field systems are far superior to pipe-in-gravel in every aspect: smaller leach field size due to optimal percolation, increased retention capability for heavy loading days, root infiltration protection for long term viability, resistance to traffic, and more. Infiltrator leach field chambers are high-density polyethylene arches that interlock to form a continuous drainage area with a much greater storage 'surge' volume than conventional pipe-in-gravel leach fields. Chamber fields are commonly given a 30% field size reduction over pipe in gravel. Standard Quick4 'Plus' Infiltrator chambers are 34 inch wide (3 foot trench) by one foot tall by 4 foot long (net length after connecting together). Best practice is to limit trench runs to 12 or 13 chambers (about 50 foot length) requiring two end caps for each row. One should never drive over any leach field, but chambers are rated for 16,000 pounds per axle load, given at least one foot of cover. Drive perpendicular to chambers, as when crossing rail road tracks, never drive down the length of a trench.

Infiltrator chamber pricing and installation tips & tricks

Septic system site plan design tips and do-it-yourself tricks

"Are we allowed to install this septic system on our property" is not a question we can answer for you. We have been providing much the same passive (non electric) septic system parts for over thirty years now, but we do not follow constantly changing city, county, and state building regulations. Unfortunately, with over 3000 counties in the United States, regulations changing from year-to-year, and interpretations of those rules varying from one inspector to another (and one engineer to the next), it's never possible to say for certain 'what is allowed' locally. We encourage clients to mail copies of their septic system plans for our free review with purchase of a system. The Natural Home is not an engineering firm; we do not provide any engineering services, soil testing or on-site work.

Best practice is to install a 1500 gallon effective net-volume two-compartment septic tank. Even when you are allowed to install a smaller tank, it will save money in the long run by having the septic tank pumped less often and a much smaller chance of eventual bio-mat formation in the leach field. Larger tanks retain effluent for a longer time, allowing solids to settle on the bottom and grease to float to the top. Plus, a larger tank will allow for adding of bedrooms later without the county requiring a larger septic tank. Every county has its own unique regulations with equations and definitions that can change yearly and always are open for interpretation. Slower percolation rates due to poorly draining soil with clay, bedrock, high ground water, proximity to a creek, or other complications require larger leach fields. There are two methods of calculating the minimum absorption area for a leach field. Traditionally, you dig an eight foot deep test inspection hole in the area of the intended leach field to allow building inspector, or your local engineer, to physically examine the soil and determine its Long Term Acceptance Rate. Or you can have a local soil testing firm perform a percolation test to clock the speed of your soil's capacity to absorb liquids. Local building code dictates the equation used to calculate how many square feet of leach field is required based upon the speed of percolation, composition of the soil, and LTAR. The Georgia Co-Op Extension Service's classic conventional septic system manual is recommended reading for understanding the basics of septic systems. A general rule-of-thumb to use when estimating is one square foot of leach field, per gallon of effluent, per day, in normal soils that percolate relatively well.

Save money by renting a backhoe and installing your own plastic septic tank for your home sewage system. Should local code dictate installing a concrete septic tank, have it seal-coated well and try to avoid rectangular vaults. The rounded end, hockey rink shape, is much stronger. Unlike concrete, plastic tanks are not affected by high ground water and saturated soils which will eventually erode concrete, forcing replacement. Plastic has many advantages over concrete in addition to durability in wet locations: consistent quality, portability without a crane truck, and three-way inlet and outlet ports. Polyethylene tanks will never crack and leak and they are easily moved around by two people, saving money on heavy equipment and making difficult locations easier to build. In most of the country, local regulatory officials allow homeowner-builders to submit a site plan and pull their own installation permits. Save money by renting a backhoe and installing your own septic system!

Stamped, engineered, septic system plans are typically not necessary unless your property percolation test was extreme (greater than 60 minutes per inch or less than 5 minutes per inch); or the site has seasonal groundwater; or there is bedrock or unsuitable soil less than four feet below the proposed leach field; or if the ground slope is in excess of 30% in the area of the proposed leach field. Engineered systems require a local professional engineer to approve (stamp) your site's septic tank and leach field plans. Anyone can draw up their own septic system plan, but legal liability then lies exclusively with your regulatory officials and they often defer to a licensed and insured local engineer. This releases the local government from future legal liability for your extreme septic system's failure. What is code in my area? is a uniquely local question and often changes yearly and varies from county to county in some states, so you need to check and see what is required on your property. Please note that we are not an engineering firm and we do not supply stamped, engineered plans, but we do consult for no charge with purchase of any complete septic system. Even professionals with 30 years in the business can get too tied up in 'how we've always done it' to realize simple improvements will make a huge difference in performance and longevity. What follows is a general guide to the average Individual Sewage Disposal System ISDS guidelines (code) in most of the country.

When you apply for your building permit, the local health department official will most likely help you design the sewage disposal system and may even offer to have their office perform a soil test (LTAR) in lieu of a percolation test. This involves digging a soil profile hole which is generally an eight foot deep trench in the area of the leach field. Most building departments wisely require a visual confirmation that there are no problematic soil conditions, groundwater, or bedrock in the area where you intend to put the leach field. But check with your local officials, as you may only need to provide a site plan survey (ILC) of your property (to establish setbacks from buildings, wells, streams, and property lines) and fill out some forms.

Your septic system site plan is typically drawn right on top of your property survey showing the septic tank 'setbacks' with tank 5-10 feet from the house, the leach field at least 20 feet from the house, at least 100 feet away from wells and streams, 25 feet away from dry gulches, and 10 feet away from the property lines. Or whatever the local regulatory officials require, so always check with the county first for minimum setbacks.

The home's sewer line drain pipe needs to slope 1/8 to 1/4 inch per foot downhill to the inlet side of the septic tank and the outlet pipe needs to flow downhill at least 1/8 inch per foot downhill to the leach field, where the septic tank effluent enters a manifold or distribution D box. Beyond the manifold or D box the leach field trenches (for an Infiltrator chamber system) are excavated perfectly level at a depth of at least seven inches below the grade of the manifold pipes or D box (for chambers). And covered with at least one foot of soil atop the trench or chamber. Trenches can be deeper, if the site dictates, but rarely more than three feet below finish grade.

If the leach field is uphill from the septic tank a lift station is installed in-line after the septic tank. An electric sump pump in the lift station tank forces effluent out to the leach field every time it fills to a certain level ("dosing"). Most ISDS codes allow field size reductions with dosing or automatic siphons, so there may be a certain advantage to installing a lift station when building on small lots and/or with nearby streams or ponds.

Never grind up (macerate) your sewage before sending to a septic tank unless absolutely necessary. Pumping treated sewage (after septic tank) up to the leach field with lift station is always an option, but do not macerate (pump) effluent prior to the septic tank. The septic tank operates by digesting solids and settling sludge to the bottom and allowing grease to float to the top of the septic tank. Macerating the sewage before entering the septic tank will create a septic tank without any large solids, just a cloud of ground up sewage particles. When you send these particles out to the leach field, you are bound to eventually clog the soil with bio-mat and then the leach field fails.

Avoid using drain cleaner, bleach or harsh detergents with a septic system. Bleach and detergents kill the helpful bacteria that thrives in a healthy septic tank to optimally process toilet waste. Lack of proper septic tank bacteria will cause your leach field to fail from excessive bio-mat accumulation.

If your system is not used enough, the septic tank can be subject to possible freezing in the winter. Steps must be taken to ensure good operation. Not pumping the tank right before winter is a good example: there is very little biological activity (bacteria consuming organics) to keep a clean sewage tank water warm. Always install waterproofing above septic tank to divert water and thus frost at least three feet away. In practice, this amounts to backfilling up to top of tank, sloping the ground away (mound) around perimeter, and then laying down a plastic tarp. If you can keep the water away from the sides of the tank, you can retain more heat in the dry ground and help speed decomposition of waste. A good tip is to set down a layer of straw before the tarp - it will cushion against rock damage and provide insulation. In extreme climates, a layer of two inch thick extruded polystyrene (EPS) foamboard insulation is recommended below the tarp.

If allowed, always divert greywater to a separate leach field. See greywater page for details. Greywater contains soaps, which are designed to kill bacteria (clean and disinfect things). You want to encourage helpful "good" bacteria (digesting anaerobic cultures) to grow in your septic tank, not kill them with soap laden graywater. If you cannot divert all of your greywater, just diverting the washing machine discharge will make a big difference in performance and eliminate a large portion of a home's effluent, taking the load off your leach field.

professional advice from over 30 years of design & service

Strip all topsoil from atop the tank, pipe, and leach field area and stockpile for revegetation later. Keep all vehicles OFF the absorption field area. After construction, protect all components from livestock and vehicle traffic.

Use lots of purple primer on all pipe joints and splash it around. Allow the inspector to clearly see that all joints were properly primed before solvent welding. Using clear primer hides the fact every joint was properly solvent welded.

First joint between pipe coming out of the home foundation and the pipe headed to the cleanout is best done with a Fernco rubber boot coupler. Flexible connection allows for some movement in effluent pipe without cracking the first joint.

Cleanout within 5 feet of the house with best practice underneath the roof eave, immediately adjacent to the foundation where it hides well in landscaping, is easier to locate, and may stay free of snow.

Septic tanks are generally required to be within 5-10 feet of foundation. NEVER any bends in the pipe prior to the septic tank to avoid solids congealing and blocking flow. Infiltrator septic tank inlet (and outlet) can be drilled on three sides, so the tank may run parallel with foundation and adapt to any layout.

Two rubber gaskets for inlet and outlet pipe holes are included with the Infiltrator tank along with two PL-68 drop-tees Please note these PL-68 drop-tees may not be pre-approved for use as inlet tees in your county. Check with local officials before installing. Inspectors may allow cutting the PL-68 down to regulation depth. If not, install a standard 'sanitary tee' fitting with drop pipe, as pictured online, usually with two 22.5 bends prior to the sanitary tee to bring the top of the fitting closer to water level. Rules vary from county-to-county, and from inspector-to-inspector, but the bottom of the inlet pipe is normally ~12 inches below tank water level. Liquid surface is measured at the outlet pipe hole, which is lower than the inlet.

Plans often show septic tank lids brought all the way to surface grade. If you do this, cover lids with geotextile fabric and mulch to protect from sunlight damage. No reason to leave plastic exposed to direct sunlight.

Recommend using 4 inch Sch40 (thicker wall) pipe for line from house to septic tank(s). Using SDR35 (thin wall) sewer pipe after septic tank to leach field is fine. One should never ever drive over any part of a leach field. Chance of collapsing pipe aside, you don't want to knock pipes or chambers out of level. If you must drive automobiles over pipe, you must install 4 inch Sch40 inside of a 6 inch outer 'protective sleeve' pipe.

All pipes must be well-bedded in up to six inches of 3/4 inch nominal crushed gravel to avoid frost issues or soil settling and heaving of pipe off-level. Pipe from foundation to septic tank slopes maximum of 1/4 inch per foot. Too steep of slope and water will bypass solid waste in the pipe, eventually clogging it. Slope minimum 1/8 inch per foot from septic tank to distribution box and leach field. Much steeper is possible, but best to level-off prior to the distribution box or the turbidity will affect equal splitting to runs.

Distribution boxes, director valves, and manifolds should be wet-set in a couple bags of Sakrete and plenty of 3/4 inch crushed gravel to maintain level and prevent frost issues. This is especially true when the d-box is located at the end of a steep slope or long run from the tank.

Infiltrator installation details are critical to leach field longevity, be it pipe-in-gravel or chambers. In main, always scarify the soil (loosen to a depth of a foot, or more) in the base of the trench prior to installing chambers. Compacted soil will not percolate properly. In poor soil conditions, 3/4 inch crushed gravel can be added to the base of the trench to further increase capacity and longevity.

Install a large splash plate underneath the chamber inlet pipe to avoid washing out soil. Ceramic tiles 16 to 24 inch square work nicely. Important detail when the leach field is located at the end of a steep slope or long run from the tank.

Always vent the end chamber 'inspection port' of each leach chamber run to ensure proper air circulation for healthy soil. With multiple 'fingers', it is possible to have less than one vent every row and interconnect them all with 4-way fittings to allow for inspection at each end. But additional ventilation from venting every end is worth it in the long run.

pumping septic tanks and refilling immediately

Check both compartments yearly and pump before enough solids accumulate in first compartment to spill over into second compartment. Usually less than sixteen inches, but consult manufacturer of your tank. Wrap a piece of white towel around the end of a long pole to check solids level in bottom of your septic tank. A healthy, properly sized septic tank might never need pumped, but not pumping when needed will result in grease and solids getting out to the leach field. Particulates, grease and solids create 'biomat' in the leach field percolation area, eventually causing it to fail and need replacement. Every two to five years is the normal cycle for pumping a septic tank. Less often in warmer areas and/or lower usages with larger tank volume. Should you live in an extremely cold climate, never have your tank pumped in the fall or winter - only pump in the spring. Septic tank water only avoids freezing through biological bacterial activity (fecal matter decomposing).

Refill your concrete or fiberglass septic tank with water immediately after having it pumped! Without any water on the inside, an empty septic tank is under extreme stress resisting the weight of backfill around it. This is especially true when soil is wet and when tanks are not properly bedded in plenty of gravelf for selective draining of backfill. Stress is exacerbated when sewage pumpers park too close, so always keep their truck at least 20 feet away. Wet concrete gets weak over the years. With enough stress, an empty concrete or fiberglass tank will crack, start leaking, and eventually have to be replaced.

never use ANY septic additives or enzyme digesters

Properly sized two compartment septic tanks operate just fine without potentially dangerous additives. Breaking down fats and solids in the septic tank with digestive enzymes simply allows these now much smaller particles to pass through the septic filter where they reunite in the leach field, forming a dense bio-mat. The FDA has never approved any additives; none are considered safe or effective. You don't want these additives finding their way into the groundwater where they can be used for irrigation and drinking. Leach field distance from the wellhead (100 to 200 feet) is no guarantee of safety, it's just an arbitrary number locally assigned to allow residential construction on smaller half acre lots. Lateral water (sewage effluent) movement underground is extremely unpredictable at certain times of the year and will easily contaminate your well. Any chemical (or enzyme) which digests sewage should frighten a reasonable person to allow in their drinking or irrigation water.

septic system effluent treatment area options

Every septic system, except the cesspool, has two distinct components: Septic Tank to catch solids and Treatment Area to dispose of liquid waste effluent. Slower percolation rates due to poorly draining soil with clay, bedrock, high ground water, proximity to a creek, or other complications require larger treatment areas. There are two methods of calculating the minimum absorption area for a leach field. Traditionally, you dig an eight foot deep test inspection hole in the area of the intended leach field to allow physically examination of the soil to determine its Long Term Acceptance Rate. Or a local soil testing firm performs a percolation test to clock the speed of your soil's capacity to absorb liquids. Local building code dictates the equation used to calculate how many square feet of leach field is required based upon the speed of percolation, composition of the soil, and LTAR. A very general 'rule-of-thumb' minimum size is "one square foot per gallon per day" minus up to a 30% reduction for using chambers instead of perforated pipe-in-gravel leach field. But that could be way off, depending upon actual soil percolation rate and estimate of daily usage. Bare minimum usage rate to estimate with is 100 gallons per person per day. Therefore the building department often uses 200 gallons per bedroom per day when sizing residential systems. The Georgia Co-Op Extension Service's classic conventional septic system manual is recommended reading for understanding the basics of septic systems.

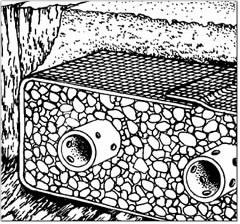

Leach Fields are trenches (or rectangular beds) dug in yard and filled with a foot of 3/4" to 1-1/2" crushed washed gravel and a four inch diameter perforated pipe. The pipe-in-gravel leach line is covered with geotextile fabric and then backfilled with a foot or two of native soil atop. Gravity sends effluent to leach field with at least a 1/8 inch per foot drop and then is dispersed into soil evenly with all of the leach field perforated pipe being at the same level. Leach fields provide better treatment of septic waste by allowing it to percolate into a greater surface area of soil.

Chamber Systems are a tried and true advancement in leach field design with arched panels in the trench for a huge amount of additional surge capacity. With no gravel inside, chambers have ample air to help keep the leach field soil aerobic and healthy. Leach field size reductions of up to 30% are common with chambers versus pipe-in-gravel.

Leach Pits are large gravel filled holes and are a common solution for small/odd lots where a long leach field is not possible. Leach pits take advantage of surface area around sides of the hole to dispose of large amounts of effluent in the right soil types. Adding a drywell to a leach pit gives it additional surge capacity. Always allow at least eight or ten feet of undisturbed soil space between leach pits to ensure maximum percolation and effluent treatment. Leach pits are not suggested for areas with high groundwater since the small amount of surface area in the base limits treatment of sewage.

Pressurized Mound Systems make use of an electric pump to force effluent into elevated mound 'constructed soil' beds. Even distribution of effluent is key to smaller leach field sizing and better sewage treatment. Poor soil percolation sites often require pressure distribution constructed sand mounds with a pump and perforated pipe.

Evapotranspiration / Drip Beds are pressurized systems with smaller holes or drip nozzles for even more uniform distribution of waste water in fragile sites with difficult soil. In areas that do not get snow cover in the winter, long shallow trenches can be run through yard, sending waste water into the root zone near surface. The grass and plants above transpire water through plant growth and evaporation being so close to surface. A much smaller portion of effluent percolates down into water table.

Constructed Water Treatment Wetlands are shallow lagoons and mainly designed in hot climates since plant life is key. Active plant growth year-round dissipates the nitrogen and truly treats the effluent. Constructed wetlands show the most promise for a carefree low-maintenance treatment area, but you do generally need to live in a non-freezing climate.

Lagoons, Cesspits, and Cesspools are man-made ponds where the effluent evaporates more than percolates, often assisted by a fountain or bubbler. Basically, a constructed wetland without the plants. Cesspools and cesspits do not have a septic tank to trap solids. When the solids build up, you dig a new pond and fill in the old one. Old-fashioned approach common to ranches for disposing of animal waste. Lagoons can be lined to prevent percolation in a fragile area. Six foot fencing and a locked gate are standard practice to keep livestock and humans from falling into the cesspool.

CLOSEOUT on geotextile soil filter fabric for leach fields and pits

Never install plastic 'visqueen' sheeting or cheap non-woven 'weed barrier' landscaping fabric in place of professional grade heavy-duty woven geotextile fabric for septic system leach fields. Besides issues with longevity, visquene plastic sheeting or cheap weed barrier non-woven materials will suffocate the soil, ultimately causing anaerobic soil conditions, biomat formation, root rot, and molding issues. Plastic sheeting becomes brittle and tears within a few years and the adhesive bond holding non-woven weed-barrier fabric threads together decomposes, allowing sand and soil to migrate into the gravel layer of leach field or French drain. Invest in our professional grade woven geotextile fabric with a full 35 mil thickness and extra heavy-duty five ounce per square yard weight and 12 gallons per square foot per minute water permeability. Our vastly superior polypropylene fabric will never rot, working indefinitely when not exposed to sunlight. Longevity and durability is ensured with heavy-duty weight and tough woven construction. Non-woven weed barrier fabrics tend to fall apart over time.

Geotextile fabric pricing, installation details, and design tips

Drywell leach pit kits to fix failed leach field or add capacity

Drywell leach pit kits are best practice for additions and repairs on pipe-in-gravel leach fields. Not venting the end of each leach field lateral line (finger) is the most common cause of leach field failure. Lack of fresh air in the leach field pipes and surrounding gravel creates anaerobic conditions, accelerating bio-mat formation. Best practice is to install at least one drywell at the end of each lateral line finger. An upgrade for longevity is two drywells installed in-series which allows the first to act as a settling catchment, ensuring long-term viability of a failing sewage disposal system by keeping the perforated pipes lines dry most of the time. Drywell system cut sheet with gravel installation detail is available for engineers.

There is no 'Miracle Enzyme Cure' or hole punching scheme that will work for any length of time. Please don't believe those ads for "all natural, biodegradable, septic safe" leach field cleaners. May buy you a couple of months, but at the risk of contaminating your groundwater. Septic waste 'digesters' are not sold here. And schemes to punch holes in your yard to cure the problem are just hustles. You have to flush the biomat out of leach field pipes before any treatment.

Hire a professional to flush out leach field lines FIRST (power jetting) prior to treatment. The first time, it requires an industrial strength pressure washer equipped with rotating root cutting blades to clear the entire four inch leach field drain pipe. There is a lot of work to do before the line jetter shows up. Septic system flushing involves hazardous human waste. Wear disposable protective clothes with full head/mouth covering, face shield and/or goggles, protected sleeves and gloves. There must be a cleanout at the start of each lateral line and another at the end. A large pit at least 2by2by3 feet deep is excavated at the end of each leach field pipe to accept the flushed out bio-mat and roots. You accomplish nothing by jetting and allowing the bio-mat to remain inside of the lateral line perforated pipes.

Peroxide treatment is best left to professionals. Hydrogen peroxide is caustic and will BURN exposed eyes and skin. Home healthcare hydrogen peroxide is around 3% with pool chemical supply stores selling barrels of 30% strength up to 50%. HazMat Placards must be posted in your front and rear window. We do not sell hydrogen peroxide.

After jetting and flushing, cap both ends and CAREFULLY pour in the industrial strength hydrogen peroxide. The expense of trying to completely fill perforated pipe with hydrogen peroxide is likely not cost-effective, but invest in enough to fill the pipe at least 1/4 to 1/3 full. Per 100 lineal feet of 4 inch diameter pipe, it takes 16 gallons to fill almost 1/4 full and 20 gallons to fill 1/3 full. Plumb cleanout with a tee fitting and gasketed garden hose adapter (3/4 inch MNPT to 3/4 MGHT). Give peroxide at least a few hours to start working on the bio-mat and then pressurize the line with water for best effect. Allow line to drain and then jet and flush again to attempt to get more bio-mat out of your lines. Lacking power jetting head for four inch pipe, you can do a passable job with a high pressure sprayer equipped with disruptor head (full circle shower spray).

You have to examine why the system failed in the first place. The most common reasons are: single compartment septic tank, no septic particulate filter, under-sized leach field, and lack of leach field ventilation. Oxygen is very important for leach field health. A drywell with surface vent at the end of lateral lines is an instant fix. Greatly increases capacity and dries out the lateral lines. Taking the load off your failing leach field is crucial to any repair.

One drywell kit provides an initial surge capacity of 48+ gallons before it starts percolating into surrounding soil. That is the same effective surge capacity as 74 lineal feet of four inch diameter sewer pipe. Gravel backfill around and under the drywells will increase the capacity of your leaching pit and extend the serviceable life expectancy. A single drywell with at least one foot of gravel under and around it (absolute bare minimum) will dispose of 200+ gallons per day in most soils, but you cannot have too large of a leaching pit. The more gravel under and around the drywell, the better for longevity.

Sample installation shown with TWO DRYWELLS in series and bringing effluent in through the lid. Top loading through the vent tee ensures maximum surge capacity. Freezing is rarely, if ever, a problem with running sewage water underground, but you can always cap the vent in deep winter, if need be. We provide all of the fittings pictured with your kit (4 inch sanitary tee, riser, coupler, and green vent grate). Plus, a 6by6 foot piece of geotextile fabric for above the gravel layer to keep backfill soil from clogging the surrounding leach pit rock. Additional fabric can be purchased above for leach pit sides. Fabric on the sides is highly recommended in sandy or silty soils or areas of high seasonal groundwater. Never place geofabric on the bottom side of a septic leach pit, only the sides and top of gravel. Drywell system cut sheet with gravel installation detail is available for engineers.

We no longer retail the NDS FWAS24, but you can purchase drywell kits online at Amazon.com. We recommend buying the following fittings for best longevity. Avoid bringing water in from the side.

- Sanitary Tee Inlet 4 inch diameter curved tee brings liquid into the top of drywell lid, not through side.

- Riser Pipe and Coupler fitting to attach green vent grate on top of sanitary tee for surface venting.

- Green Vent Grate flat slotted drain fitting allows for inspection and fresh air down into drywell through lid.

- Woven Geofabric commercial-duty 5 ounce per sq yd to cover top of gravel and sides (not pit bottom).

We are clearing out the last of our NDS FWSD69 surface drains (9" tall with 6" grate). Sold as a set of Twelve (12) for $179 total delivered via UPS.

In stock

A single drywell is plumbed as seen on right-hand unit. The four inch inlet pipe comes into side of kit's sanitary tee on the lid, with riser, coupler and vent grate on ground surface. Two drywell kits are installed in-series for optimal leach pit longevity. Ordering a second drywell kit for in-series design allows first drywell to act as a sediment catch-basin, with surge overflow eventually cascading over into the second drywell. This is standard and best practice in poorly percolating soils and helps ensure leach pit longevity.

Two drywells can be installed in a single leach pit (hole filled with gravel), but best practice is two holes separated by at least six to eight feet of undisturbed soil. Loosen 'scarify or till' soil at least one foot deeper than the base of leach pit before adding gravel. For optimal percolation, avoid compacting 'smearing' soil in base of hole and sides. While possible to install gravel-less, using the soil you just removed from hole for backfill, always best to install at least one or two feet of 3/4 to 1-1/2 inch gravel under and around drywell.

Septic and greywater systems should use crushed washed aggregate, not round river rock. Minimum 'nominal' 3/4 inch is typical and often referred to as a #57 crushed. Up to 1-1/2 inch aggregate can be used, but it gets harder to shovel and may not be quite as effective for septic system effluent treatment. Avoid 'pea gravel', chips and fines, dirt and sand. Avoid using larger gravel or round river rock. Gravel smaller than 3/4 inch will fall through the one inch knock-out holes in side of drywell. Never put gravel on the inside of the drywell, only around the exterior.

It is not necessary to have more than two drywells to dispose of additional water, just larger leach pit(s) filled with more gravel. The "system capacity" is not limited by the number of drywells, only the size of the gravel filled leach pit hole(s) and speed of soil percolation. Larger leach pits ensure longevity of soil percolation by allowing more time for effluent to percolate into soil. Your local building department sets the equations (code) used to determine minimum leach pit size for septic systems and yard drainage. Knowing the actual percolation rate of the soil is the only way of being certain, so you need to hire a local soil engineer to be positive when leach pit sizing. A rule of thumb in well percolating soil is up to about 200 gallons per day, every day, with at least 1 foot of gravel under and around the drywell. Initial 'surge potential' with two drywells is at least 100 gallons. Drywell system cut sheet with gravel installation detail is available for engineers.

drywell kits for small property septic system leach pits

Sewage disposal septic systems are commonly designed as gravel-filled leach pits with drywell(s) on smaller properties. Drywell system cut sheet with gravel installation detail is available for engineers. Leach pits disturb much less surface area than a leach field of perforated four inch diameter sewer pipe in a shallow gravel bed. Seasonal groundwater must not be a local issue when designing deeper leach pits. Please note two critical design errors in the second sketch... 1) Never install bends in the four inch diameter sewer pipe before the septic tank. Bends after the tank are fine since the water has been filtered of solids, but you don't want to clog the line coming into the tank. 2) always install a cleanout in the sewer pipe immediately after it leaves the home foundation. Should that line clog or freeze, you need a means to access it. Maintain 1/8 to 1/4 inch per foot drop from house to inlet side of septic tank. Any steeper, and water might flow too fast and pass right around toilet waste. From the outlet side of septic tank, effluent can flow downhill at a much steeper angle. Always 'bed' all pipe and tank well, in plenty of gravel. A 6-8 inch layer or 3/4 to 1 inch diameter aggregate is recommended. Gravel ensures accurate pipe slope in trenches since this size crushed rock only compacts about 3% to 5% later. Bedding pipe prevents dips and flat spots where sewage might collect. In a cold climate, it is critical to avoid allowing sodden soil (frost) from touching your pipe and tank. Even in a warm climate, septic tanks are able to maintain healthy bacteria levels and 'digest' sewage more readily when warm. Bedding a septic tank in gravel can make all the difference between having your tank pumped every three years to maybe once every five or six years.

Note corrections: 1) always install a clean-out for the line immediately after foundation

2) must be straight-shot from foundation to septic tank, never any bends as pictured

3) always bed all pipe and septic tank in ~6 inches of gravel for level and warmth

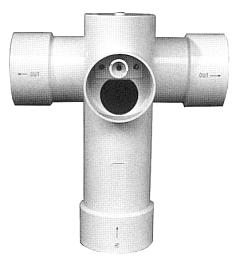

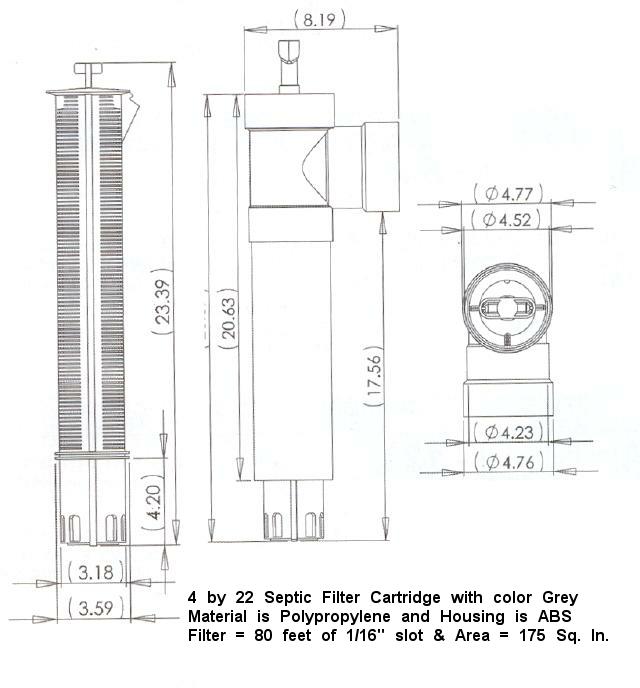

Lifetime, self-cleaning septic filter never needs replaced

Every septic tank system MUST have a filter to prevent particulates from entering the leach field. Particulates combine over the years to form a black sludge layer in the bottom of your leach field, called 'bio-mat'. Bio-mat clogs the soil, preventing percolation and eventually causing total failure with sewage backing up into the house. Best practice is a two-compartment septic tank with septic filer in the outlet side of second compartment. Should you have an existing single compartment septic tank, then you really should add a second, smaller settling tank in-line afterwards. Locally sourced tanks will save a great deal of money given freight cost on such large items. Choose a tank that is rated for 'dry burial', meaning it can be buried without water inside and not risk collapsing from weight of soil atop and around. Tanks as small as about 75 gallons and 40 inch tall are adequate for a greywater system, but installing at least 300 to 500 gallon second compartment tank is typical for a septic system in most areas of the country. The larger the tank, the longer the retention time and better function. As a last resort, filter can be installed inside a single compartment septic tank, but 'self-cleaning' function may be compromised.

Our time-tested NSF/ANSI certified standard #46 septic filter assembly has a universal hub for use with either SDR35 thin-wall or Sch40 thick wall 4 inch diameter pipe. This lifetime service filter is self-cleaning in normal use, with a natural sloughing action to prevent bio-mat buildup. Features 80 lineal feet of filtration area for up to 800 gallons per day treatment volume. Built-in gas deflector on the bottom provides secondary 1/2 inch filtration to prevent larger solids from entering inside. A series of 1/16 inch horizontal filtration slots, rather than a mesh screen, provides much less surface area for solids to attach themselves. Patented flow pattern reduces trapping of solids inside the filter by allowing sediment to slough-off and fall back into the tank for further digestion. Filter features a locking tab to prevent ‘floating’. Solids are not allowed to pass-by even when tank surges occasionally. This time-tested care-free septic filter design never needs replacing.

Septic tank filter kit pricing, installation details, and design tips

We no longer ship septic filter kits outside of Colorado. For our Infiltrator system clients, this dependable kit comes complete with filter, housing tee that fits Sch40 or SDR35 four inch pipe, and a handle extension kit. You'll never have to replace this lifetime service septic filter. Best to hose it off once a year to be sure, but generally this septic tank filter is self-cleaning, shedding debris back into tank.