Infiltrator IM-540, CM-1060, and IM-1530 septic tanks

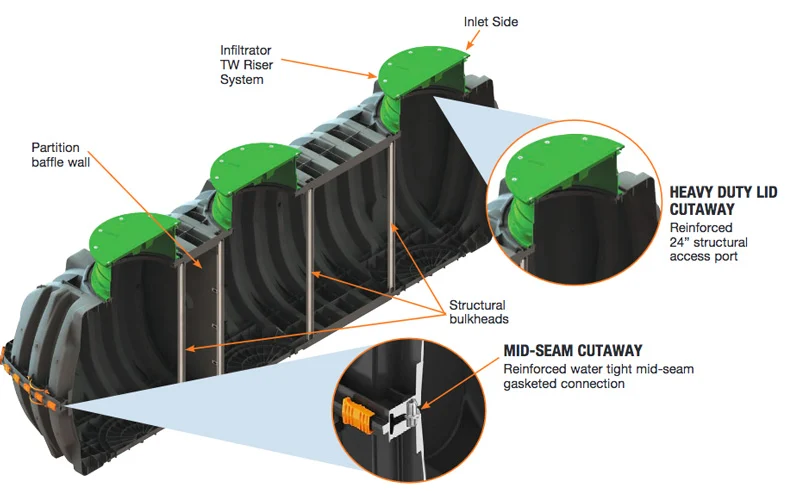

Infiltrator's IM Series injection molded (and CM compression molded) polypropylene septic sewage tanks feature heavily-ribbed bodies capable of dry burial up to four feet deep, structurally reinforced manways, fiberglass bulkheads, and advanced mid-seam gasketed connections which make them far superior to rotationally molded plastic tanks. There is no strength difference between compression and injection molding, it is simply a different technique whereas rotationally molded septic tanks are far weaker one-piece construction which requires being filled with water before backfilling. Infiltrator heavy-duty septic tanks are rated for dry burial up to 4 feet deep. IM-540 single compartment has a 552 gallon working capacity at 5 foot 5 inch (65") long, 5 foot 2 inch (62") wide, 4 foot 7 inch (55") tall, and 170 pounds. CM-1060 two compartment has a 1111 gallon working capacity at 11 foot 2 inch (134.2") long, 61.7 inch wide, 54.5 inch tall, and 331 pounds. IM-1530 two compartment has a 1537 gallon working capacity at 14 foot 8 inch (176") long, 5 foot 2 inch (62") wide, 4 foot 7 inch (55") tall, and 500 pounds. Lifting ropes are installed for ease of installation without a crane. We have not sold any other brand of plastic septic tank for many years because Infiltrator tanks have proven to be the very best.

Minimum order delivery is FREE within about a 50 mile radius of central Denver. We range North to Fort Collins & Greeley, South to Franktown & Monument, East to Deer Trail & Tampa, West to Georgetown & Silver Plume, and SouthWest to Bailey & Conifer. Delivery a few miles outside of this radius is possible for larger orders. We can schedule an AM or PM delivery window given at least three days advance notice, weather permitting. Designated receiver must be on site and waiting with backhoe to unload tanks using installed lifting ropes. Or you can will-call pick up in person at our central Denver area warehouse with a pre-paid order. Payment at the yard and C.O.D. are not possible to arrange. Warehouse hours are 7:30 AM to 4 PM on Monday through Thursday and 7:30 AM to 2 PM on Friday. Infiltrator products are not shipped outside of Colorado. Outside of Colorado, contact InfiltratorWater.com at info@infiltratorwater.com or 800-221-4436.

For over 30 years, we've been providing FREE consultation to our clients. Engineered site plans are always the bare minimum acceptable standards, never mentioning optional parts. Permits never discuss design choices that will improve performance and safety, increase longevity, expedite construction, or prepare for future repairs. We encourage clients to mail a copy of their septic system site plan for free review with purchase of an Infiltrator system. Please note The Natural Home is not an engineering firm. We do not provide any engineering, site plan drafting, county permitting, or on-site services. We assist clients with parts list development while discussing options to ensure they order what is best for their project.

service@thenaturalhome.com or call 800-563-9720

No delivery outside of Colorado. No credit card over $2000.

Only bank wire, cashier's check, or postal money orders.

Apologies for any inconvenience, but we cannot afford fraud.

C.O.D. and payment at the yard are not possible to arrange.

All Infiltrator parts are always in stock for will-call & delivery.

Infiltrator's heaviest-duty

dry-burial rated septic tanks

$2078 IM-1530 1537 gallon capacity

2 compartment, 3 manhole 62" wide by 55" high by 176"

Kit includes 3 lids, 2 rubber grommets & 2 PL-68 drop tees

$1598 CM-1060 1111 gallon capacity

2 compartment, 2 manhole 61.7" wide by 54.5" by 134.2"

Kit includes 2 lids, 2 rubber grommets & 2 PL-68 drop tees

$1028 IM-540 with 552 gallon capacity

1 compartment, 1 manhole 62" wide by 55" by 65" long

IM-540 tank kit includes 1 grommet & 1 PL-68 drop tee

The following parts only available

with an Infiltrator tank purchase...

EZ Snap stackable risers $73 each for 12" tall

$46 for 6" tall risers and $34 for 2" tall risers

At least one 12 inch riser per manway in Colorado climate

Infiltrator tanks are rated for dry burial up to four feet deep

$43 Safety Star manway grids fit inside risers

Perhaps not required on permit, but sensible insurance

$107 (MC & VISA ok) Septic tank filter kit

Every tank needs an outlet filter - No parts to ever replace

Comes with housing and handle, plus a free 5" hole saw

$399 Fluid Dynamics FDS216 siphon installed

non-electric 2" outlet 16" draw-down installed in IM-540

approximately 190 gallons of effluent per dosing cycle

$49 7-hole Tuf-Tite distribution box

Free plugs & seals with Tuf-Tite D-box

$22 each for 6 inch tall D-box risers

Often required to bring lid up to grade

$2 each for D-box speed levelers

Equal flow and allows shut-off to runs

$59 9-hole Tuf-Tite distribution box

Free plugs & seals with Tuf-Tite D-box

$53 each for 12 inch tall Tuf-Tite risers

$30 each for 6 inch tall Tuf-Tite risers

$32 each for green domed riser lids

$229 10-hole Rhino distribution box

24" diameter with Ten (10) potential openings

Four Free 3001-SN seals fit 2", 3" or 4" pipes

Seal install requires 5-1/8" (130mm) hole saw

Here is a 5-1/8" hole saw on Amazon for $14

$7 each for additional 3001-SN seals

$32 each for 2 inch tall Rhino risers

$53 each for 6 inch tall Rhino risers

$88 each for 12 inch tall Rhino risers

$727 300 gallon spherical pump tank

54" diameter by 51" tall with elevated pump stand on bottom

44" to inlet center and 42" to outlet center 8" square flat areas

$277 for 15" tall risers & $327 for 24" tall risers

Pipe & fittings are less expensive at HomeDepot or Lowes

Pumps, floats, and alarm control panels best found online

We can source special parts with any septic system purchase

Septic tank installation videos

Infiltrator septic tank installation

Inlet and outlet hole preparation

Tank bedding & backfill details

EZsnap riser safety star install

Tank buoyancy control guide

service@thenaturalhome.com

for Infiltrator tank questions

Infiltrator septic tank system parts list options

* 1500 gallon Septic Tank is always recommended when a 1000 gallon tank is 'allowed' on your permit. Especially in a cold climate, the additional 50% volume translates into longer retention time for better settling of waste and much greater leach field protection against bio-mat formation. The investment pays off big in the long run by pumping the septic tank less often and ensuring leach field longevity. Plus, a 1500 gallon tank may allow for adding more bedrooms to your home in the future.

* Manhole Risers must be installed on all manways to allow lid removal at ground level without dirt falling into the tank. Two (2) manways on the IM-1060 and Three (3) on the IM-1530 tank with 2, 6, and 12 inch tall risers available. Tanks can be buried up to four feet deep, with burial at least 12 inch deep the norm. The lid is generally covered with geotextile fabric and a few inches of mulch, gravel, or pavers to protect it from sunlight damage. This product cannot be shipped later.

* Safety Star Grids may not be "required" by your engineer, but they are a most highly recommended common-sense safety feature. These 250 pound rated reinforced fiberglass safety grids screw into the manway risers with enough space left open in the center to insert a septic pumper hose and remove the filter for cleaning. This product cannot be shipped later.

* Septic Tank Filter should always be installed on the outlet side of all septic tanks. Rated for up to 800 gallons per day, our kit comes with a handle extension and PL-68 'Versa-Tee' housing which can adapt to a 4 inch SDR35 or Sch40 pipe. Kit includes a free hole saw kit for cutting 5 inch diameter holes for septic tank inlet and outlet. This product ships via UPS Ground.

* Geotextile Soil Fabric can be installed above chambers to prevent migration of surrounding soils and keep it from entering the chambers. Recommended in wet and potential flooding areas with sandy or silty soil. Our 4 foot wide rolls of best heaviest-duty woven 5 ounce geotextile fabric ship separately via free UPS Ground.

* D-Box Speed Levelers are insurance against distribution boxes ever being knocked out of level. They can be adjusted to evenly split flow to all outlet pipes. Speed levelers also allow you to shut flow off to individual runs seasonally, so they can dry out and recuperate. This product cannot be shipped later.

* D-Box 6 inch risers bring the distribution box lid up closer to the surface so you can adjust the speed levelers. Local regulations may require risers for ease of inspection and maintenance. The D-box lid is normally covered with geotextile fabric and a few inches of mulch, gravel, or pavers to protect it from sunlight damage. This product cannot be shipped later.

geotextile fabric for leach fields & liners for mounds

$199 free UPS for 4' by 250' 5 oz woven geofabric atop Infiltrators to stop sand & silt

Following fabrics are only available with purchase of an Infiltrator system. Not shipped separately.

Please note that all Infiltrator and geotextile fabric prices are subject to change without any notice.

$157 for 6 foot by 300 foot (200 sq yd) of 2 ounce sq yd non-woven polypropylene

$257 for 10 foot by 300 foot (333 sq yd) of 2 ounce sq yd non-woven polypropylene

$307 for 12 foot by 300 foot (400 sq yd) of 2 ounce sq yd non-woven polypropylene

$769 for 12 foot 6 inch by 360 foot (500 sq yd) of 4.2 ounce sq yd non-woven 'Mirafi'

$929 for 15 foot wide by 360 foot (600 sq yd) of 4.2 ounce sq yd non-woven 'Mirafi'

$477 for 6.35 foot by 100 foot roll (635 sq ft) of 30 mil PVC mound liner membrane

over 30 years of do-it-yourself design tips and rules of thumb

* Strip all topsoil from atop components and stockpile for revegetation later

* Return all soil, mounding atop leach field to encourage rain to drain away

* Keep all livestock, vehicles, and snow storage OFF tank and leach field

* Septic tank up to 10 feet away and leach fields 20+ feet from foundation

* Never install any bends between house foundation and the septic tank

* Always install risers on manholes to prevent soil intrusion when servicing

* Avoid exposing septic tank lids - best to cover with soil, pavers, or mulch

* Always install a cleanout in sewer line near home foundation for servicing

* Slope four inch pipe 1/8 to 1/4 inch per foot, never any steeper before tank

* Bed all pipe and tank in at least 6 inches of gravel to prevent frost issues

* Always install a septic filter in the second compartment, outlet side of tank

* Never use 'septic treatments' as they do more harm than good to leach field

* Likewise, avoid harsh detergents, bleach, disinfectants, and drain cleaners

* Never install geotextile fabric on the bottom of leach pit or drainage trench

All installation tips detailed here apply equally to any brand or type of septic tank. With 64 very independent counties in Colorado, each with their own unique set of regulations, and an infinite variety of site and soil conditions, we cannot predict what will be required. Always check with your building department to confirm local regulations prior to planning any septic or greywater system to confirm what is required for your property. The Natural Home is not an engineering firm; we do not provide any engineering services, soil testing or on-site installation work.

Always install at least one manway riser above every septic tank manhole. Without a riser, it is impossible to open lid for servicing without sending debris down into the tank's manhole. Conventional to install at least one 12 inch tall riser for each manway, but you can certainly bury deeper in a cold climate. Infiltrator tanks are rated for dry burial up to four feet deep. Risers are stack-able available in 2, 6, and 12 inch tall and snap together (no screws needed). Lid should be buried at least a few inches below grade, deeper burial in a cold climate. Even in the warmest climate, best practice is to cover lids with landscaping fabric and mulch or native soil to protect against UV damage. Manway safety grids should be installed on every manhole to prevent accidents. Fiberglass reinforced, manway safety grids screw into place within the riser for a solid installation with enough open room in the center of the grid to allow insertion of septic pumper hose and removal of the septic filter for cleaning. Infiltrator Safety Stars for installation in the 24 inch diameter EZsnap riser.

cold climate installation guidelines

In a cold climate, especially with minimal snow cover, it is critical to bed tanks in plenty of +/- 3/4 inch gravel. Round river rock is fine for bedding pipe and tanks. Avoid large 2+ inch rocks and sharp, crushed gravel. It is possible to set tanks atop a sand bed to make it easier to level, but sides and top must be gravel in a cold climate. By bedding in at least eight inches of gravel, cold water and frost cannot come in contact with the sides and bottom. Take the additional step of covering the top of the tank with a reinforced poly tarp (or pond liner) that extends at least five feet in every direction and mounding underneath to encourage water to drain away. For more insurance in the coldest climates, and when usage is minimal, add at least 2 inches of foamboard insulation underneath the tarp, on a flat substrate before mounding. Dry soil is warm soil. A few inches of foam board insulation glued and screwed to the bottom of lids is best practice in colder climates. Warmer septic tanks provide for faster, better waste treatment which protects leach field longevity.

bed all leach field pipe in plenty of gravel

All pipes must be well-bedded in at least six inches of +/- 3/4 inch gravel to avoid frost issues or soil settling and heaving pipe off-level. Best practice is first connection (joint) at effluent pipe coming out of foundation be made with rubber boot coupler. Common mistake is solvent welding that first joint with a hard fitting and not bedding pipe. Should the newly installed pipe run settle, a rubber boot coupler will adapt, unlike solvent welded joint. Pipe from foundation to septic tank slopes maximum of 1/4 inch per foot. Too steep of slope and water will bypass solid waste in the pipe, eventually clogging it. Slope minimum 1/8 inch per foot from septic tank to distribution box and leach field. Much steeper is possible, but best to level-off prior to the distribution box or the turbidity will affect equal splitting to runs. Use lots of purple primer on all pipe joints and splash it around to allow inspector to clearly see everything was properly primed before solvent welding.

Four inch diameter sewer pipe comes directly from cleanout, immediately adjacent foundation, to the septic tank. No bends should be installed between house and septic tank or toilet waste may settle in the line and eventually block flow. After the septic tank, sewer pipe can make bends as need be. Just maintain 1/8 to 1/4 inch per foot slope until the septic tank. Greater slope than 1/4 inch per foot may allow water to flow around toilet waste, allowing it to settle and block flow. Less than 1/8 inch drop per foot and you may leave flat sections or dips that can freeze. When designing site plan, you are not limited to coming in one end of tank and out the opposite end. Infiltrator tanks can be plumbed from three directions on both ends.

Critical detail is to bed all pipe, fittings, and distribution boxes well in at least six inches of gravel to ensure level is maintained and frost is not an issue. Best practice is to 'wet-set' distribution box atop a bag or three of Quikrete to ensure level is maintained. Wet-set refers to pouring dry concrete mix under and around and then wetting it with water. You can pre-mix the concrete or set with minimal water in the field with 'fence post' dry mix. Fill the bottom of D-box with water up to hole openings to give it some weight. Water will exit all outlet holes evenly when box is perfectly level. Bringing lid up to near the surface with D-Box risers will allow use of Speed Levelers to dial-in accurate distribution. Rotating speed levelers upside down allows individual runs to go fallow and dry out seasonally to help protect longevity.

Concerning the use of Sch40, SDR35, or ASTM 3034 pipe in septic systems, SDR35 'sewer, drain, vent' pipe with 3034 fittings is adequate for wastewater systems outside the home foundation. Sch40 thick wall pipe is only required for pressurized water systems. Sch40 might help should you ever drive over the system, but one should never ever drive over any pipe. At the very least, you may create a dip in the line and block flow. Should you be forced to drive over a section of pipe, always 'sleeve' the four inch pipe inside an outer six inch Sch40, or thicker, galvanized metal pipe.

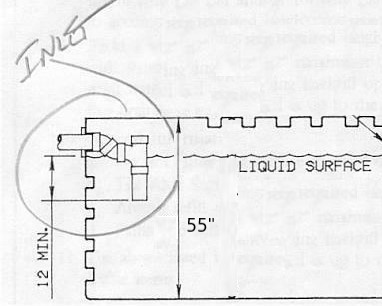

Two rubber gaskets for inlet and outlet pipe holes are included with Infiltrator septic tanks along with two PL-68 drop-tees. Please note these PL-68 drop-tees may not be approved for use as inlet tees in your county. Check with local officials before installing. Inspectors may allow cutting the PL-68 down to regulation depth. If not, install a standard 'sanitary tee' fitting with drop pipe, as pictured, usually with two 22.5 bends prior to sanitary tee to bring top of fitting closer to water level. Rules vary from county-to-county, and from inspector-to-inspector, but bottom of inlet pipe is normally ~12 inches below tank water level. Liquid surface is measured at outlet pipe hole, which is lower than inlet. Inlet hole in the septic tank is generally two inches higher than outlet hole to prevent sewage back-up.

In the long run, a 1500 gallon tank will save money by having the septic tank pumped less often and the leach field is less subject to bio-mat formation due to untreated, less-clarified effluent. Septic tank size depends entirely upon local building code requirement, which is spelled out in the Individual Sewage Disposal System ISDS regulations for your area (local building code). Every county has its own unique regulations with equations and definitions that can change yearly and always are open for interpretation. In practice, a 1000 gallon (working capacity), two compartment, septic tank is considered the minimum size requirement for an up to three bedroom home, with at least 1500 gallon working capacity recommended at four bedroom. The larger the septic tank, the slower and more thoroughly it processes the solid waste and the less often it needs to be pumped. Septic tank sizing is best determined by usage and how long effluent stays in the tank before it goes out to the leach field. Consider a thirty hour sewage treatment retention time to be the bare minimum, with larger tanks allowing more time for solids to settle on the bottom and grease to float to the top. Less daily flow means more clarified liquid receiving treatment prior to disposal in the leach field. Plus, a larger septic tank may allow you to add a bedroom or two later without the county requiring a larger septic tank. Nice selling point, adding value to any home.

three compartment septic tanks with a pump

When the leach field is located on ground higher than the septic tank, a pump is added. You do not want to install this 'lift station' pump in the second compartment of the initial septic tank. Tank level should remain constant and relatively undisturbed to encourage optimal settling (clarification) of sewage waste. Traditionally, a third compartment lift station tank is installed in-line after the initial two compartment septic tank. The IM-540 has a capacity of 552 gallons, for plenty of flexibility with draw-down 'dosing' amounts. By increasing the amount of effluent sent to leach field at one time (dosing) you can effectively give yourself several hundred gallons of capacity (many toilet flushes) when your pump eventually fails.

plastic versus concrete septic tanks

Quality plastic tanks are superior to crack-prone concrete. If local code dictates installing a concrete septic tank, have it seal-coated well and avoid rectangular vaults since the rounded end, hockey rink shape, is much stronger. Sewage is highly alkaline, continuously eroding sodden concrete so that it will eventually crack or fail entirely. Prevent the outside of your concrete tank from contacting sodden soil and your longevity will improve. Always fill a concrete septic tank full of water immediately after having it pumped. Without water on the inside of those concrete walls, there is no strength to resist backpressure. High groundwater and saturated soils from a heavy rain right after pumping your septic tank can be a disastrous combination. Polyethylene tanks will never crack (or leak) and plastic is easily moved around by two people, saving time and money on heavy equipment (no crane needed) and making difficult locations easier to build. Take steps to ensure vehicles cannot travel near the septic tank. Traffic alongside can displace backfill and subject the side of a tank to undue pressure where it is least able to resist. If you cannot build a fence or set Sch80 four inch steel pipes in concrete for a barrier, at least drive numerous T stakes and cover them with pipe and reflectors. In a commercial traffic area, one should consider pouring a rebar-grid heavily reinforced concrete pad atop and alongside the tank for ultimate protection.

In most of the country, local regulatory officials allow homeowner-builders to submit a site plan and pull their own installation permits. Stamped, engineered, septic system plans are typically not necessary unless your property percolation test was extreme (greater than 60 minutes per inch or less than 5 minutes per inch); or the site has seasonal groundwater; or there is bedrock or unsuitable soil less than four feet below the proposed leach field; or if the ground slope is in excess of 30% in the area of the proposed leach field. Engineered systems require a local professional engineer to approve (stamp) your site's septic tank and leach field plans. Anyone can draw up their own septic system plan, but legal liability then lies exclusively with your regulatory officials and they often defer to a licensed and insured local engineer. This releases the government from future legal liability for your extreme septic system's failure. What is code in my area? is a uniquely local question and often changes yearly and varies from county to county in some states, so you need to check and see what is required on your property. Please note that we are not an engineering firm and we do not supply stamped, engineered plans, but we do consult for no charge with purchase of any complete septic system. Even professionals with 30 years in the business can get too tied up in 'how we've always done it' to recognize improvements which make a huge difference in system performance and longevity. Save money and get a longer-lasting project by renting a backhoe and installing your own plastic septic tank.

Individual Sewage Disposal System ISDS rules vary

* When you apply for building permit, the local health department official will most likely help you design the sewage disposal system and may even offer to have their office perform a soil test (LTAR) in lieu of a percolation test. This involves digging a soil profile hole which is generally an eight foot deep trench in the area of the leach field. Most building departments wisely require a visual confirmation that there are no problematic soil conditions, groundwater, or bedrock in the area where you intend to put the leach field. But check with your local officials, as you may only need to provide a site plan survey (ILC) of your property (to establish setbacks from buildings, wells, streams, and property lines) and fill out some forms.

* Your septic system site plan is typically drawn right on top of your property survey showing the septic tank and leach field 'setbacks' with tank 5-10 feet from the house, the leach field at least 20 feet from the house, at least 100 feet away from wells and streams, 25 feet away from dry gulches, and 10 feet away from the property lines. Or whatever the local regulatory officials require, so always check with the county first for minimum setbacks. Ensure easy access to septic tank for the pumper truck. Clear any obstacles while you have the backhoe on site and consult with pumping company about how close they need to get with their truck. If they have to drag hose very far it will cost you.

* The home's sewer line drain pipe needs to slope 1/8 to 1/4 inch per foot downhill to the inlet side of the septic tank and the outlet pipe needs to flow downhill at least 1/8 inch per foot downhill to the leach field, where the septic tank effluent enters a manifold or distribution D box. Beyond the manifold or D box the leach field trenches (for an Infiltrator chamber system) are excavated perfectly level at a depth of at least seven inches below the grade of the manifold pipes or D box (for chambers). And covered with at least one foot of soil atop the trench or chamber. Trenches can be deeper, if the site dictates, but rarely more than three feet below finish grade.

* If the leach field is uphill from the septic tank (or if the local health regulations simply require it) a lift station is installed in-line after the septic tank. An electric pump in the lift station tank forces effluent out to the leach field every time it fills to a certain level 'dosing'. Most ISDS codes allow field size reductions with dosing or automatic siphons, so there may be an advantage to installing a lift station when building on small lots and/or with nearby streams or ponds. We do not sell pumps since they are readily available locally and electricians tend to prefer supplying parts.

* Never grind (macerate) your sewage before sending to septic tank unless absolutely necessary. Pumping treated sewage (after septic tank) up to the leach field with lift station is always an option, but do not macerate (pump) effluent prior to the septic tank. The septic tank operates by digesting solids and settling sludge to the bottom and allowing grease to float to the top of the septic tank. Macerating the sewage before entering the septic tank will create a septic tank without any large solids, just a cloud of ground up sewage particles. When you send these particles out to the leach field, you are bound to eventually clog the soil with bio-mat and then the leach field fails.

* Never use bleach, drain cleaner, or harsh soaps with a septic system. Bleach and detergents kill the helpful bacteria that thrives in a healthy septic tank to optimally process toilet waste. Lack of proper septic tank bacteria will cause your leach field to fail from excessive bio-mat accumulation.

* Winter freezing is rare with proper installation and constant usage. Always have your tank pumped in the spring, never in the fall, or low bacterial activity may fail to keep the sewage warm. Surface freezing inside a septic tank can be avoided by bedding tanks in at least one foot of gravel (crushed or river rock). Drainage of the area under and around tank and above the tank, with waterproof tarp diverting drainage at least three feet away. If you can keep the water away from the sides of the tank, you can retain more heat in the dry ground and help speed decomposition of waste. In practice, this amounts to backfilling up to top of tank, sloping the ground away (mound) around perimeter, and then laying down a plastic tarp. A good tip is to set down a layer of straw before the tarp - it will cushion against rock damage and provide insulation. In extreme climates, a layer of two or four inch thick extruded polystyrene (EPS) foamboard insulation can be installed below the tarp.

* If allowed, always divert greywater to a separate leach field (see the greywater page for details). Greywater contains soaps, which are designed to kill bacteria (clean and disinfect things). You want to encourage helpful "good" bacteria (digesting anaerobic cultures) to grow in your septic tank, not kill them with soap laden graywater. If you cannot divert all of your greywater, just diverting the washing machine discharge will make a big difference in performance and eliminate a large portion of a home's effluent, taking the load off your leach field.

pumping tanks and a warning to immediately refill

Check both compartments yearly and pump before enough solids accumulate in first compartment to spill over into second compartment. Usually less than sixteen inches, but consult manufacturer of your tank. Wrap a piece of white towel around the end of a long pole to check solids level in bottom of your septic tank. A healthy, properly sized septic tank might never need pumped, but not pumping when needed will result in grease and solids getting out to the leach field. Particulates, grease and solids create 'biomat' in the leach field percolation area, eventually causing it to fail and need replacement. Every two to five years is the normal cycle for pumping a septic tank. Less often in warmer areas and/or lower usages with larger tank volume. Should you live in an extremely cold climate, never have your tank pumped in the fall or winter - only pump in the spring. Septic tank water only avoids freezing through biological bacterial activity (fecal matter decomposing).

Refill your concrete or fiberglass septic tank with water immediately after having it pumped! Without any water on the inside, an empty septic tank is under extreme stress resisting the weight of backfill around it. This is especially true when soil is wet and when tanks are not properly bedded in plenty of gravelf for selective draining of backfill. Stress is exacerbated when sewage pumpers park too close, so always keep their truck at least 20 feet away. Wet concrete gets weak over the years. With enough stress, an empty concrete or fiberglass tank will crack, start leaking, and eventually have to be replaced.

never use ANY septic additives or enzyme digesters

Properly sized two compartment septic tanks operate just fine without potentially dangerous additives. Breaking down fats and solids in the septic tank with digestive enzymes simply allows these now much smaller particles to pass through the septic filter where they reunite in the leach field, forming a dense bio-mat. The FDA has never approved any additives; none are considered safe or effective. You don't want these additives finding their way into the groundwater where they can be used for irrigation and drinking. Leach field distance from the wellhead (100 to 200 feet) is no guarantee of safety, it's just an arbitrary number locally assigned to allow residential construction on smaller half acre lots. Lateral water (sewage effluent) movement underground is extremely unpredictable at certain times of the year and will easily contaminate your well. Any chemical (or enzyme) which digests sewage should frighten a reasonable person to allow in their drinking or irrigation water.

septic system effluent treatment area options

Every septic system, except the cesspool, has two distinct components: Septic Tank to catch solids and Treatment Area to dispose of liquid waste effluent. Slower percolation rates due to poorly draining soil with clay, bedrock, high ground water, proximity to a creek, or other complications require larger treatment areas. There are two methods of calculating the minimum absorption area for a leach field. Traditionally, you dig an eight foot deep test inspection hole in the area of the intended leach field to allow physically examination of the soil to determine its Long Term Acceptance Rate. Or a local soil testing firm performs a percolation test to clock the speed of your soil's capacity to absorb liquids. Local building code dictates the equation used to calculate how many square feet of leach field is required based upon the speed of percolation, composition of the soil, and LTAR. A very general 'rule-of-thumb' minimum size is "one square foot per gallon per day" minus up to a 30% reduction for using Infiltrator chambers instead of perforated pipe-in-gravel leach field. But that could be way off, depending upon actual soil percolation rate and estimate of daily usage. Bare minimum usage rate to estimate with is 100 gallons per person per day. Therefore the building department often uses 200 gallons per bedroom per day when sizing residential systems. The Georgia Co-Op Extension Service's classic conventional septic system manual is recommended reading for understanding the basics of septic systems. The very first step for any septic system installation is to strip all topsoil from atop the tank, pipe, and leach field area and stockpile for revegetation later. Keep all vehicles OFF the absorption field area. After construction, protect all components from livestock and vehicle traffic.

Leach Fields are trenches (or rectangular beds) dug in yard and filled with a foot of 3/4" to 1-1/2" gravel and a four inch diameter perforated pipe. The pipe-in-gravel leach line is covered with geotextile fabric (landscaping weed barrier) and then backfilled with a foot or two of native soil atop. Gravity sends effluent to leach field with at least a 1/8 inch per foot drop and then is dispersed into soil evenly with all of the leach field perforated pipe being at the same level. Leach fields provide better treatment of septic waste by allowing it to percolate into a greater surface area of soil.

Chamber Systems are a tried and true advancement in leach field design with arched panels in the trench for a huge amount of additional surge capacity. With no gravel inside, chambers have ample air to help keep the leach field soil aerobic and healthy. Leach field size reductions of up to 30% are common with chambers versus pipe-in-gravel.

Leach Pits are large gravel filled holes and are a common solution for small/odd lots where a long leach field is not possible. Leach pits take advantage of surface area around sides of the hole to dispose of large amounts of effluent in the right soil types. Adding a drywell to a leach pit gives it additional surge capacity. Always allow at least eight or ten feet of undisturbed soil space between leach pits to ensure maximum percolation and effluent treatment. Leach pits are not suggested for areas with high groundwater since the small amount of surface area in the base limits treatment of sewage.

Pressurized Mound Systems make use of an electric pump to force effluent into elevated mound 'constructed soil' beds. Even distribution of effluent is key to smaller leach field sizing and better sewage treatment. Poor soil percolation sites often require pressure distribution constructed sand mounds with a pump and perforated pipe.

Evapotranspiration / Drip Beds are pressurized systems with smaller holes or drip nozzles for even more uniform distribution of waste water in fragile sites with difficult soil. In areas that do not get snow cover in the winter, long shallow trenches can be run through yard, sending waste water into the root zone near surface. The grass and plants above transpire water through plant growth and evaporation being so close to surface. A much smaller portion of effluent percolates down into water table.

Constructed Water Treatment Wetlands are shallow lagoons and mainly designed in hot climates since plant life is key. Active plant growth year-round dissipates the nitrogen and truly treats the effluent. Constructed wetlands show the most promise for a carefree low-maintenance treatment area, but you do generally need to live in a non-freezing climate.

Lagoons, Cesspits, and Cesspools are man-made ponds where the effluent evaporates more than percolates, often assisted by a fountain or bubbler. Basically, a constructed wetland without the plants. Cesspools and cesspits do not have a septic tank to trap solids. When the solids build up, you dig a new pond and fill in the old one. Old-fashioned approach common to ranches for disposing of animal waste. Lagoons can be lined to prevent percolation in a fragile area. Six foot fencing and a locked gate are standard practice to keep livestock and humans from falling into the cesspool.